Water jet cutters, sometimes referred to as a water jet or waterjet, are industrial instruments that cut a wide range of materials using a high-pressure jet of water or a solution of water mixed with abrasive media. Read More…

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

At M.A.R.'s Engineering Company, Inc., we specialize in providing top-notch waterjet cutting services, catering to a multitude of industries. Our team of experts, armed with cutting-edge technology, can precisely cut a variety of materials, including metals, plastics, glass, ceramics, and more. No job is too big or too small for us; we've got the expertise and equipment to handle it all.

At Fruehauf Manufacturing, we take pride in delivering precision-engineered solutions through our expertise in water jet cutting. Our advanced capabilities allow us to cut a wide range of materials with exceptional accuracy, meeting the demands of industries that require intricate designs and high-quality finishes. By utilizing state-of-the-art water jet cutting technology, we offer a...

At KL Engineering, Inc., we have built our reputation around precision, innovation, and a steadfast commitment to quality in CNC machining. As a team of engineers and skilled machinists, we bring together advanced technology and decades of expertise to deliver solutions that meet the most demanding specifications.

More Water Jet Cutter Companies

How Does Waterjet Cutting Work?

A high-pressure stream of water combined with an abrasive substance is used in waterjet cutting to cut a variety of materials. The water is pressurized by a high-pressure water pump. High-pressure tubing carries this water to the cutting head. The water passes via a nozzle inside the cutting head to create an incredibly fine stream. Whatever is placed in front of this stream is cut.

Types of Waterjet Cutting Methods.

- Abrasive waterjet cutting

- Pure waterjet cutting

Abrasive waterjet cutting

Abrasive waterjet cutting (AWJC) is a good method for cutting of hard or poorly machinable materials including titanium alloys, ceramics, metal-matrix composites, concrete, and boulders. In order to increase the machinability of some materials, this technique uses the impact of both awaterjet and abrasives. The reciprocating pump, which is used to pump clean water at an incredibly high pressure of 4000–6000 bar, is the key component of an abrasive-waterjet arrangement. The waterjet receives the abrasive particles from a hopper in the mixing chamber. Waterjet and abrasives work well together to cut or shape composite materials, Kevlar polymers, hardened steels, and some ceramic materials. In abrasive-waterjet machining, regulating the depth of cut presents the most difficulty.

Pure Waterjet Cutting

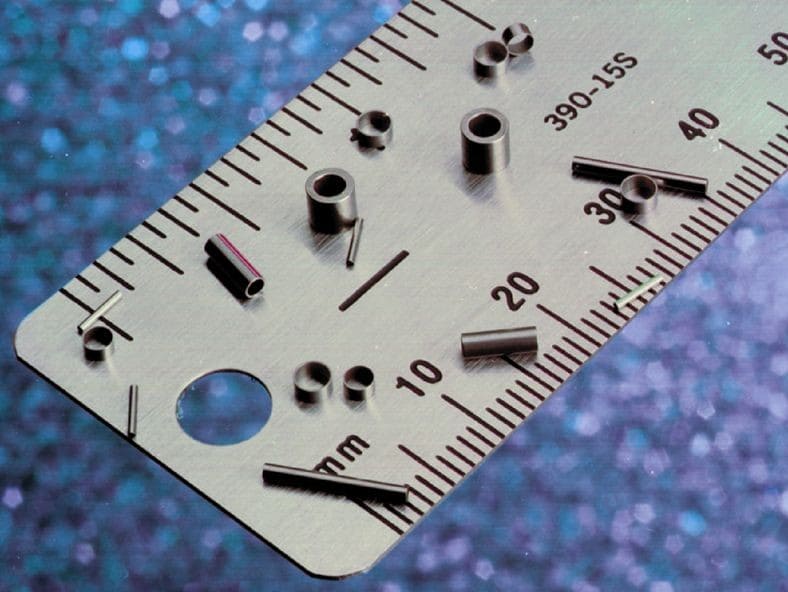

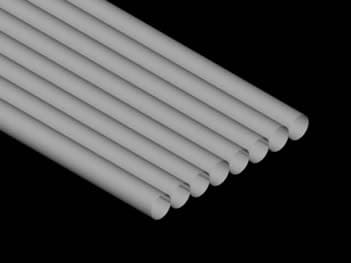

To make 0.1 mm-wide slices, pure waterjet cutting heads exclusively use a high-pressure jet stream of water. The cutting head only consists of a pressure valve and orifice because this technique doesn't require the use of an abrasive. Up to 16 cutting heads can be mounted along a single beam. To ensure the system's smooth operation, the cutting head must be changed frequently because it is fragile.

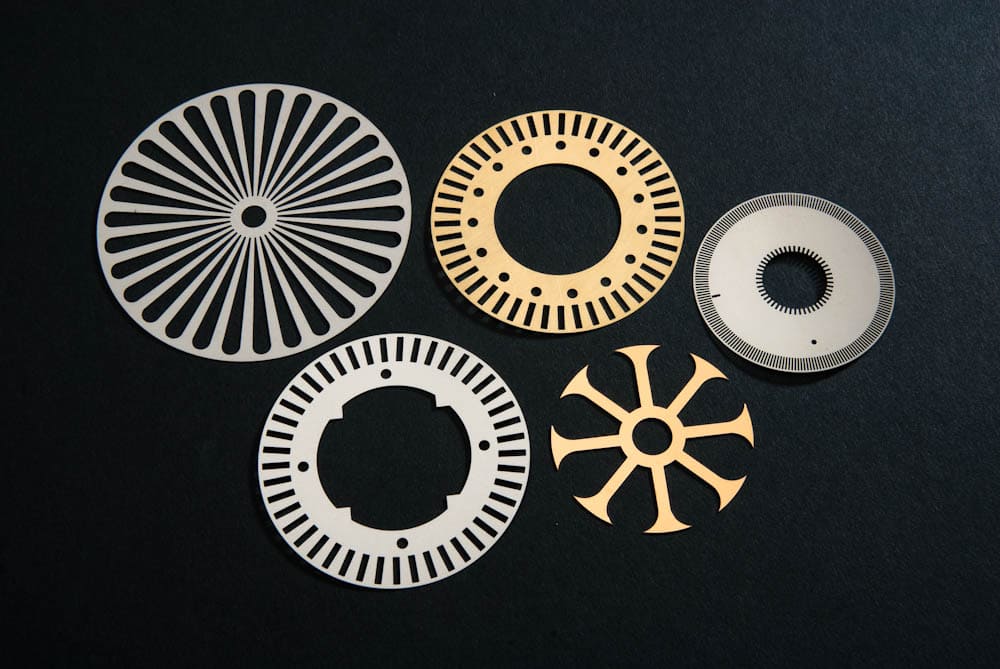

Various materials can be sliced, drilled, and cleaned with water jet cutters. The high-pressure water flow or jet is guided by the waterjet cutter's end tool. Aerospace, automotive, electronic, food, textile, packaging, and other industries use water jet cutters extensively.

Advantages of Waterjet Cutting

Waterjet cutting has a number of advantages and great options for both broad and highly specialized applications. The following are a few of the advantages:

- Heat-free zone

- High precision

- No need for tool changes

- Cost-effective process

- No need to switch out tools

- Process that is affordable, compatible with a variety of materials, and highly sustainable

High cutting accuracy is a benefit of waterjet cutting.

Even when constrained by strict standards, waterjet cut parts are of exceptionally good quality. A water jet cutting machine may produce parts with tolerances as tight as 0.025 mm (0.001 inches), however for pieces with a thickness of less than an inch, tolerances between 0.075 and 0.125 mm are more typical. Depending on the technology, tolerances may rise with thicker materials. Cutting speed, pressure, abrasive flow rate, and nozzle size are only a few of the variables that affect the final product's quality. For the best results, the process settings might need to be changed.

No need to switch tools.

A waterjet cutter does not require the use of any cutting tools, and it can accommodate a variety of materials and thicknesses without changing the nozzle. The cutting stream characteristics, such as feed rate, are changed to reach the right cutting speed, allowing the same nozzle to be utilized for a variety of applications. The water jet cutting machine can cut several materials one after the other without needing to change tools, which increases operational efficiency by saving time and money on tools.

Cost-efficient method

In many applications, especially in the food business, waterjet cutting is more economical than alternative cutting techniques. The production speed is increased since fixtures, jigs, and clamps are not usually necessary. This method also has the advantage of allowing one to stack and cut multiple layers of material in a single pass. Stacking is a straightforward but efficient approach to increase part production because it may be done with materials that are not identical to one another. Additionally, cut parts don't need to be post-processed, which lowers the overall cost. There isn't much material waste produced by the operation.

Suitability for various materials

The type of material is not a restriction on the waterjet cutting technique, as was previously stated. As long as the proper process variables and abrasives are chosen, it can cut a variety of materials. This subject will be covered in more detail later on in the article.

Materials Used for Cutting

- Metals

- Wood

- Rubber

- Ceramics

- Glass

- Stone and tiles

- Food

Choosing the Right Water Jet Cutters Company

To make sure you have the most beneficial outcome when selecting water jet cutters, it is important to compare at least 4 water jet cutter companies using our water jet cutter directory. Each water jet cutter has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each water jet cutter company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple water jet cutter companies with the same form.

Broaching

Broaching CNC Machining

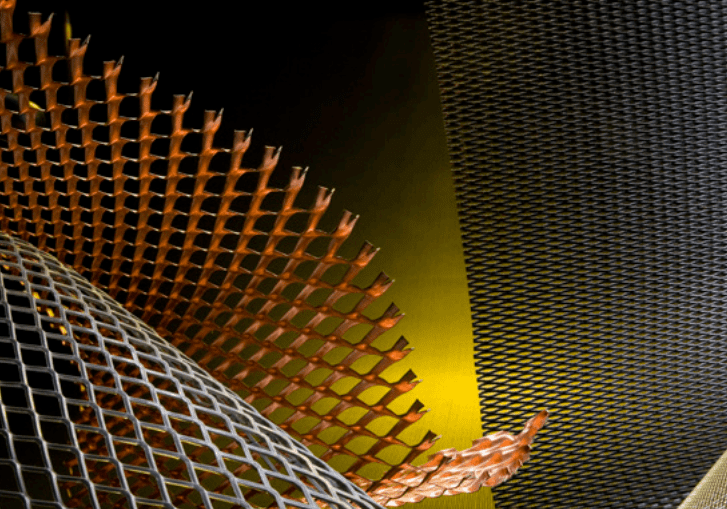

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

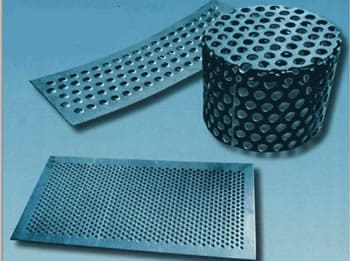

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

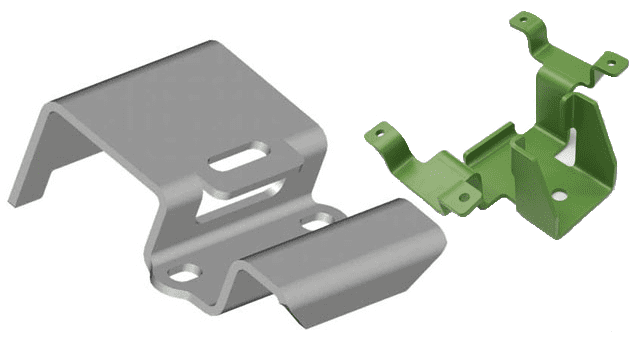

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services