Waterjet cutting (water jet cutting), also known as hydro cutting, is an industrial process with which manufacturers can cut materials. The process uses a high-pressure stream of water or water combined with an abrasive substance. Read More…

MetPlas is your single source for cutting edge contract manufacturing. This ISO 9001-2008 registered manufacturer offers expertise in lean manufacturing & a wide range of precision machining, waterjet cutting & assembly of metals & plastics. OEM’s have relied on MetPlas for decades to meet their quality, schedule & budget needs. The logical choice for virtually any contract manufacturing...

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

As a full-service waterjet machining center, RTD Manufacturing uses waterjet cutting in the manufacture of our products. Besides waterjet cutting, we also use EDM wire cutting; detail and manual machining; CNC machining plus production drill and tap. We have prototype manufacturing to offer as well.

Arcadia operates one of the largest waterjet job shops in the eastern U.S., manufacturing custom-cut parts and shapes for a variety of industries. We provide waterjet cutting services using large capacities and 5-axis water jet machining. Allow our experience to improve your manufacturing process.

We provide top of the line water jet cutting here at West Coast Waterjet. We are ISO 9001:2008 certified and our experts have a wide experience of waterjet cutting for a wide variety of industries. Our services are for virtually any material and we will work with you every step of the way. Please give us a call today to learn more information!

More Waterjet Cutting Companies

Applications

Waterjet cutting equipment is used to create new shapes and modify existing ones in parts and products. It also serves as a complement to other cutting processes like plasma cutting and metal laser cutting.

Customers of waterjet cutting services and products span various industries, including aerospace, automotive, industrial equipment fabrication, communications, metallurgy, and food processing. Additionally, lumberyard workers and artists utilize these services.

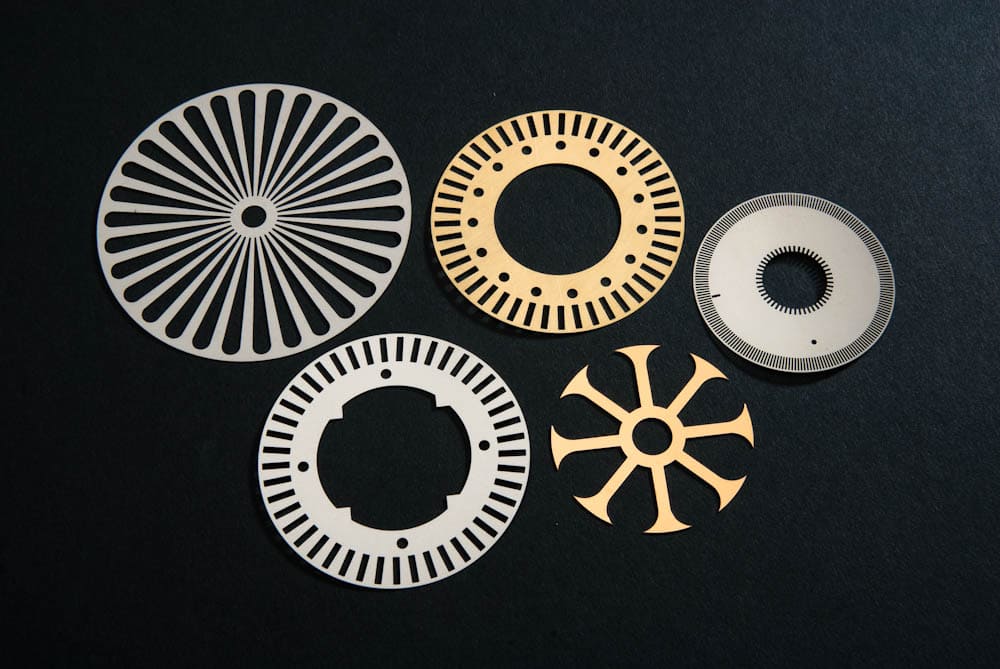

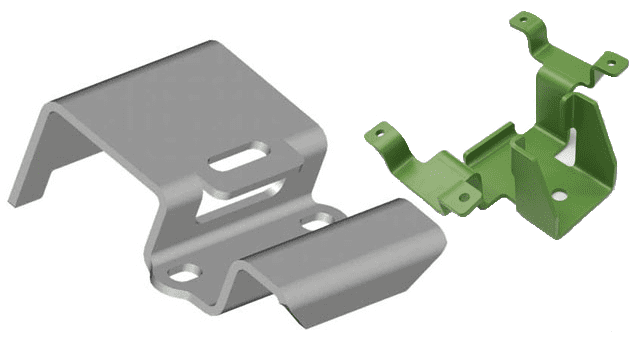

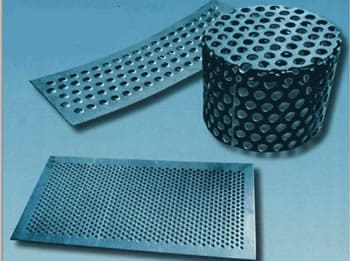

Products Produced

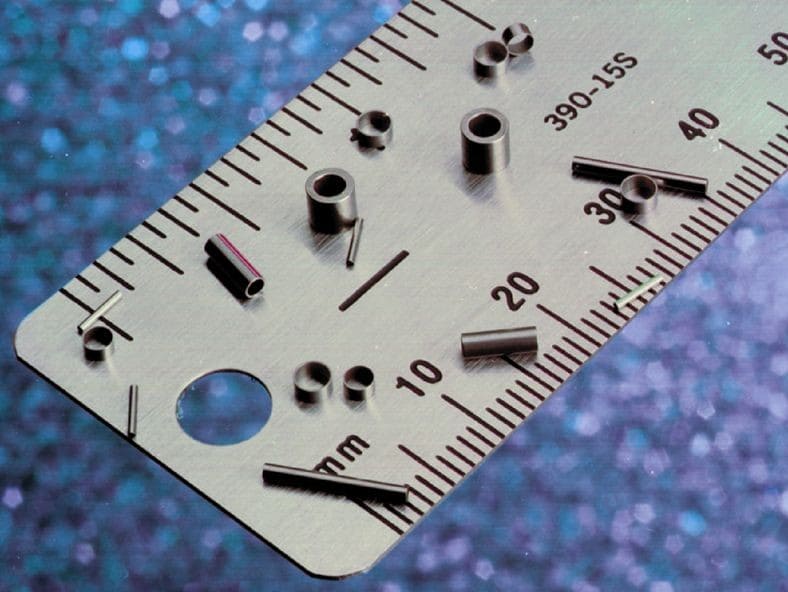

With waterjet cutting, manufacturers can produce a wide variety of parts and products. Common examples include interlocking hardware (such as bolts and gears), car parts, electronic components, large assembly line products, and design prototypes. Additionally, artists can utilize waterjet cutting to create geometrically precise and complex sculptures.

History

Water jets were first utilized in the 1800s in South Africa and New Zealand to wash away loose coal, rocks, and other debris during mining, helping miners avoid hazards related to falls, slides, and ricochets.

In the 1930s, water jets began to be used industrially for cutting. For instance, in the Soviet Union, water cannons exerting around 7000 bars of pressure were employed to cut large rocks. Meanwhile, in the United States, a Wisconsin-based company called the Paper Patents Company used narrow water jets to cut paper by integrating a moving waterjet nozzle into machines that metered and reeled continuous paper. In 1956, Carl Johnson developed a waterjet cutting machine capable of cutting shapes into plastic.

While the Soviets advanced in cutting hard materials with waterjets, American engineers struggled with cutting anything beyond soft materials until the late 1950s. In 1958, Bille Schwacha of North American Aviation invented the first waterjet cutting system powerful enough to slice hard materials like stainless steel using hypersonic liquid delivered from a 100,000 psi pump.

Building on Schwacha’s system, engineers worked to enhance waterjet cutting capabilities. In 1962, Philip Rice of Union Carbide developed a pulsing water jet that cut stones and metals using 50,000 psi. Later in the decade, researchers determined the optimal nozzle shape for delivering the strongest and most precise high-pressure jet for stone-cutting.

In the 1970s, American engineers designed water jet cutters using drill technology to deliver 40,000 bars of pressure and discovered the effectiveness of abrasives in material finishing.

In 1982, Dr. Mohamed Hashish published the first scholarly work on abrasive water jets and their efficiency in cutting hard materials. He received a patent for Abrasive Waterjet (AWJ) cutting in 1987.

In the 1990s, Dr. John Olsen and his team at OMAX Corporation developed new computer software to control nozzle movement, merging CNC technology with waterjet cutters. This innovation allowed for the creation of complex shapes with tighter tolerances. In the early 2000s, engineers introduced zero taper water jets, known as dynamic waterjets.

A key development in abrasive water jet technology has been the creation of durable nozzles, such as those made from tungsten carbide composite, capable of withstanding very high pressures. Today, engineers are working on developing commercially viable micro abrasive waterjet technology, and the industry is expected to gain new capabilities, becoming more efficient and environmentally friendly over time.

Materials

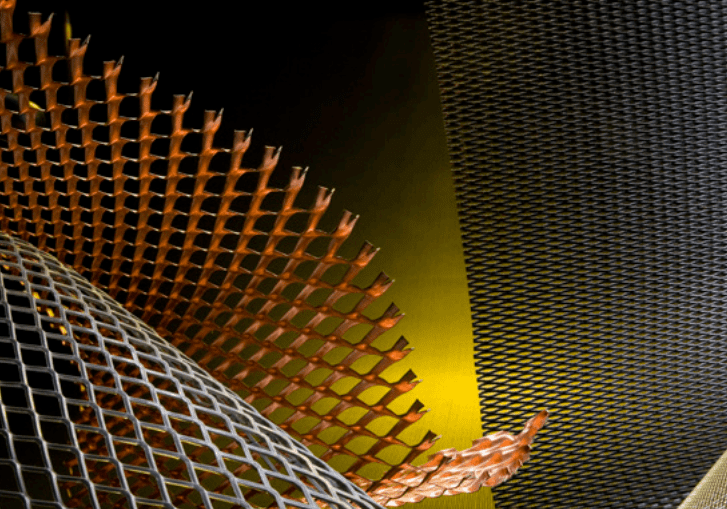

Waterjet cutters can work on a variety of materials, including plastics such as acrylics, rubber, steel, aluminum, copper, granite, plexiglass, cork, wood, and certain ceramic and glass materials.

While waterjet cutting is an impressive technique, it is not suitable for all materials. For instance, some ceramics and glass can be too fragile and may shatter when exposed to waterjets. Conversely, materials like diamonds are too hard to be cut with waterjets. Additionally, hydrophobic and moisture-sensitive materials cannot be processed with waterjet cutting.

Process Details

Before the waterjet cutting process begins, operators program the equipment to cut at the desired pressure levels. Waterjet cutters typically operate between 30,000 and 90,000 PSI, but systems designed for cutting very strong or thick materials can reach up to 120,000 PSI. Once the pressure is set, operators authorize the machine to start.

During operation, the following occurs:

First, water runs through the high-pressure pump. Then, it travels through high-pressure tubing to the nozzle. If an abrasive spray is used, the water mixes with the abrasive at this stage. Inside the nozzle, an aperture focuses the water into a thin stream. Finally, the machine ejects the water stream from the nozzle. As the water contacts the workpiece material, it cuts through with extreme precision and force.

Design

Waterjet cutting service providers can tailor their equipment and design process elements to achieve optimal results for your specific application. They customize various aspects of the process and machinery, including jet stream pressure, the type and presence of adhesives, aperture size and spacing, aperture material, and CNC involvement.

Waterjet cutter operators adjust the jet stream strength based on the material characteristics. For brittle materials like ceramics and glass, lower pressure and no abrasives are used to prevent unwanted breakage. In contrast, cutting tougher materials requires abrasive water jet cutters, which combine fine abrasives with water in a high-pressure stream.

Machinery Used

Waterjet cutting machines can handle product runs of all sizes and often feature multiple heads that operate simultaneously. To enhance precision and efficiency, these machines are typically controlled by CNC (computer numerical control) systems. CNC-managed systems execute software-designed operations, allowing for reduced space between cutouts, fewer errors, less material waste, and faster turnaround times.

A standard waterjet cutting machine consists of several key components: a nozzle, a nozzle muff, high-pressure fittings, an attenuator, apertures, a catch tank or secured holding, and CNC programming.

The nozzle, sometimes referred to as a mixing or focusing tube, directs water through the apertures and is usually made from stainless steel.

The nozzle muff, made of a brush or sponge, prevents splashing.

High-pressure fittings have side holes that ensure any leaking liquid disperses safely rather than blasting out under pressure.

The attenuator maintains and regulates the water output pressure.

Apertures , often made from ruby, diamond, or sapphire and therefore called jewels, focus the water into a precise beam as it exits the nozzle.

The catch tank collects stray water and debris for reuse by the operators.

Waterjet CNC programming integrates software and electronics to control the cutter’s movements.

Variations and Similar Processes

Waterjet cutting encompasses various methods, including abrasive waterjet cutting, abrasive flow machining (AFM), pure waterjet cutting, and CNC waterjet cutting.

b>Abrasive water jet cutting, also known as abrasive jet machining, involves mixing water with abrasive materials such as garnet, diamond, or sand. This technique is frequently used for cutting or eroding metals and shaping stone, brick, and marble.

Abrasive flow machining (AFM) is a secondary process used by manufacturers to refine hard-to-reach and internal sections of products and machinery. It offers services such as burr removal, crack removal, polishing, and smoothing.

Pure waterjet cutting, the original waterjet cutting process, does not use any abrasives. It is suitable for cutting softer materials like paper, rubber, and cloth.

CNC waterjet cutting incorporates CNC software into the waterjet cutting process to achieve precise cuts.

Benefits

Waterjet cutting services are favored by customers for a variety of reasons, including precision, cold-cutting, material reclamation, environmental friendliness, efficiency, cost-effectiveness, low worker injury rates, and adaptability.

Precision

Unlike conventional cutting methods, such as blade cutting, waterjet cutting does not produce burrs or imperfections, resulting in parts with smooth, precise edges. When combined with CNC machining, precision waterjet cutting machines can cut patterns and holes in various shapes and sizes with high accuracy.

Cold-Cutting

Waterjet cutting is a cold-cutting process, unlike laser cutting which uses heat. This offers several advantages, including the elimination of risks associated with heat, such as warping, discoloration, or other damage. Additionally, it allows for the cutting of heat-sensitive materials without the risk of ignition or melting. The cold-cutting nature of waterjet cutting also enhances efficiency, enabling the simultaneous cutting and stacking of multiple sheets of raw material.

Material Reclamation

Waterjet cutting services are highly efficient in material reclamation. Service providers can collect, sort, and reuse most of the abrasive media and water expelled from waterjet cutting machine nozzles. This not only saves time and money but also reduces environmental impact and promotes sustainability.

Efficiency

Waterjet cutting is a low-energy, high-efficiency process, combining the best of both worlds. It can rapidly produce precise shapes without consuming excessive energy.

Cost-Effectiveness

Waterjet cutting services have low material costs and offer fast, easy setup and simple maintenance. Additionally, operations can run for up to 20 hours straight, making waterjet cutters highly cost-effective.

Rate of Worker Injury

Waterjet cutting presents a low risk of workplace accidents or injuries, making it a safer option for workers.

Adaptability

Waterjet cutting is highly adaptable and can be quickly adjusted for new applications. Manufacturers can use it to cut patterns into materials for emerging technologies, demonstrating its versatility.

Selecting a Service Provider

If you are interested in waterjet cutting services, it is crucial to partner with a reliable service provider. To assist you in finding the ideal supplier, we have compiled a list of some of the best options available. To narrow down your choices, consider your specific application requirements, standard criteria, timeline, budget, delivery needs, and post-delivery preferences (such as installation assistance, parts replacement, warranties, etc.).

We recommend reviewing the waterjet cutting companies we have listed, using your specifications as a guide. Select three or four companies and contact each one for a quote. After communicating with representatives from each company, compare their services and capabilities, then choose the one that best meets your needs. Good luck!

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services