Water jet machining is also known as water jet cutting. Water jet machining is frequently employed in various industrial applications. Softer materials like plastic, rubber, and wood can be sliced with WJM. However, an abrasive material is combined with water to cut tougher objects, such as metals or granite. Abrasive water jet machining (AWJM) is the machining technique in which an abrasive material is employed in water and applied by a very high-pressure jet of water to the workpiece to achieve the desired shape and size, or to remove materials off the surface of a workpiece. Read More…

MetPlas is your single source for cutting edge contract manufacturing. This ISO 9001-2008 registered manufacturer offers expertise in lean manufacturing & a wide range of precision machining, waterjet cutting & assembly of metals & plastics. OEM’s have relied on MetPlas for decades to meet their quality, schedule & budget needs. The logical choice for virtually any contract manufacturing...

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

As a full-service waterjet machining center, RTD Manufacturing uses waterjet cutting in the manufacture of our products. Besides waterjet cutting, we also use EDM wire cutting; detail and manual machining; CNC machining plus production drill and tap. We have prototype manufacturing to offer as well.

Arcadia operates one of the largest waterjet job shops in the eastern U.S., manufacturing custom-cut parts and shapes for a variety of industries. We provide waterjet cutting services using large capacities and 5-axis water jet machining. Allow our experience to improve your manufacturing process.

We provide top of the line water jet cutting here at West Coast Waterjet. We are ISO 9001:2008 certified and our experts have a wide experience of waterjet cutting for a wide variety of industries. Our services are for virtually any material and we will work with you every step of the way. Please give us a call today to learn more information!

More Water Jet Machining Companies

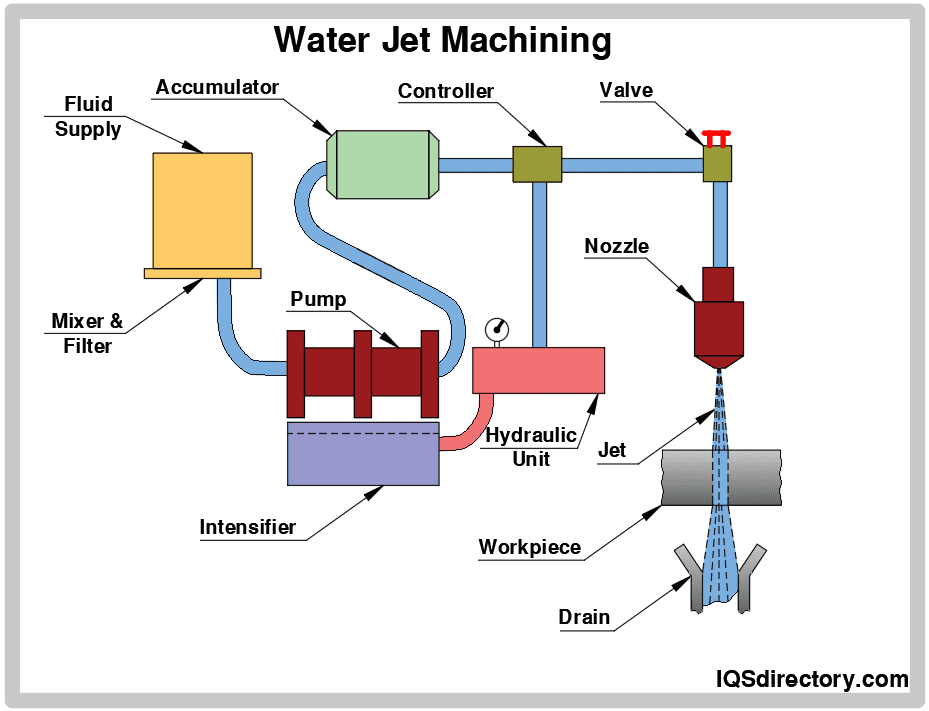

Working Theory of Water Jet Machining

The foundation of water jet machining (WJM) is the idea of water erosion. Material removal occurs when a fast-moving jet of water impacts the surface. Softer materials are machined using a pure water jet. However, some abrasive particles mixed with water for machining are used to cut tougher materials, and this process is known as AWJM.

Abrasive Substances for Water Jet Machining

The abrasive particles’ purpose is to improve the water jet's capacity for cutting. Garnet and aluminum oxide are the two abrasive materials used in AWJM the most frequently. Glass beads and sand (Si02) are additional abrasives used regularly.

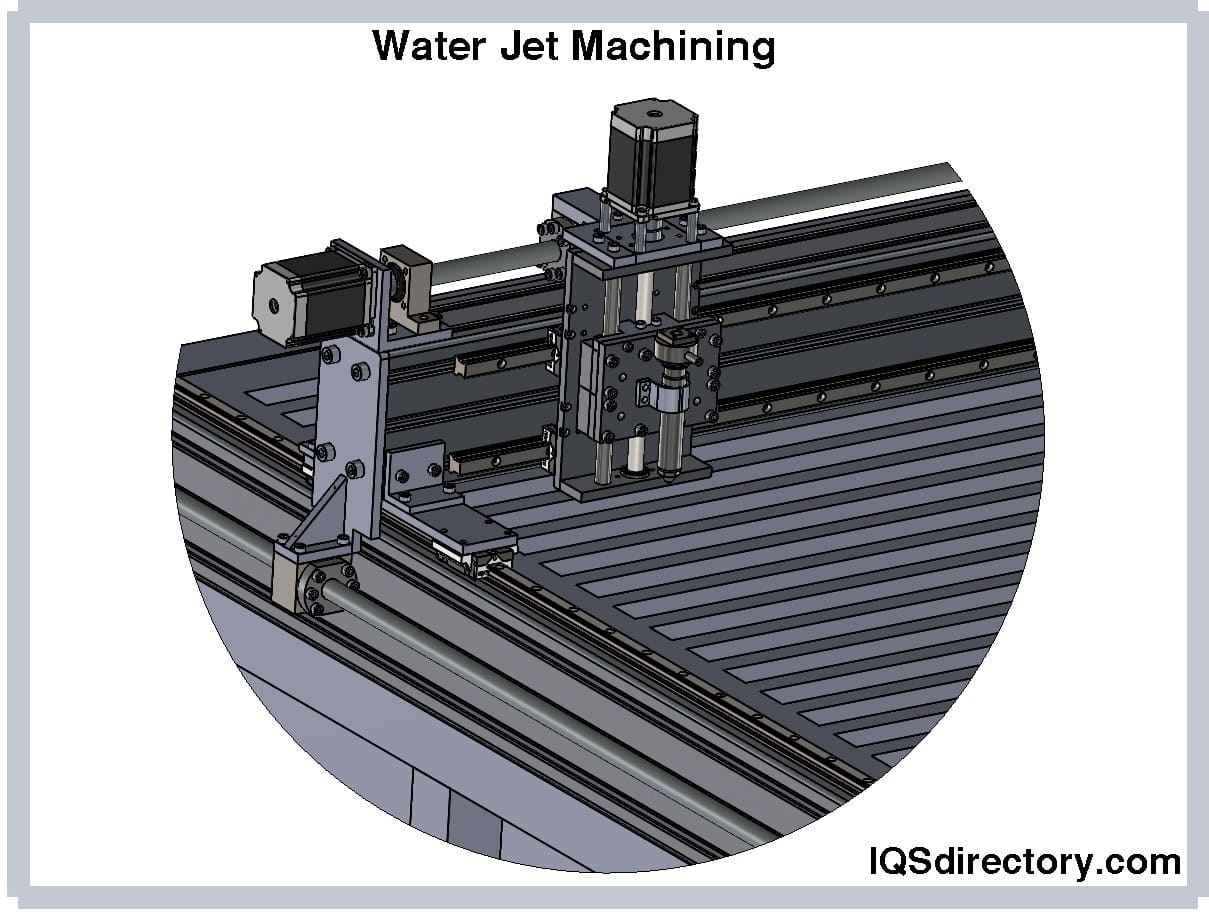

Principal Components of Water Jet Machines

The main components of water jet machines include:

Hydraulic Pump

During the machining process, it circulates the water from the storage tank. Then, water is delivered to the intensifier by the pump at a low pressure of approximately 5 bars. Additionally, a booster raises the water's starting pressure to 11 bars before transferring it to the intensifier.

Hydraulic Intensifier

It is used to raise the water's pressure to extremely high pressure. It gets water from the pump at a pressure of 4 bar and raises it to between 3000 and 4000 bar.

The Accumulator

The high-pressure water is temporarily stored there. When a significant amount of pressure energy is needed, it provides that fluid. It gets rid of the machining process's pressure fluctuation circumstances.

A Mixing Tube or Chamber

The blending of abrasive particles and water takes place in a vacuum chamber.

Control Valve

This device controls the water jet's pressure and direction.

Flow Regulator or Valve

The flow regulator assists in controlling the water's flow.

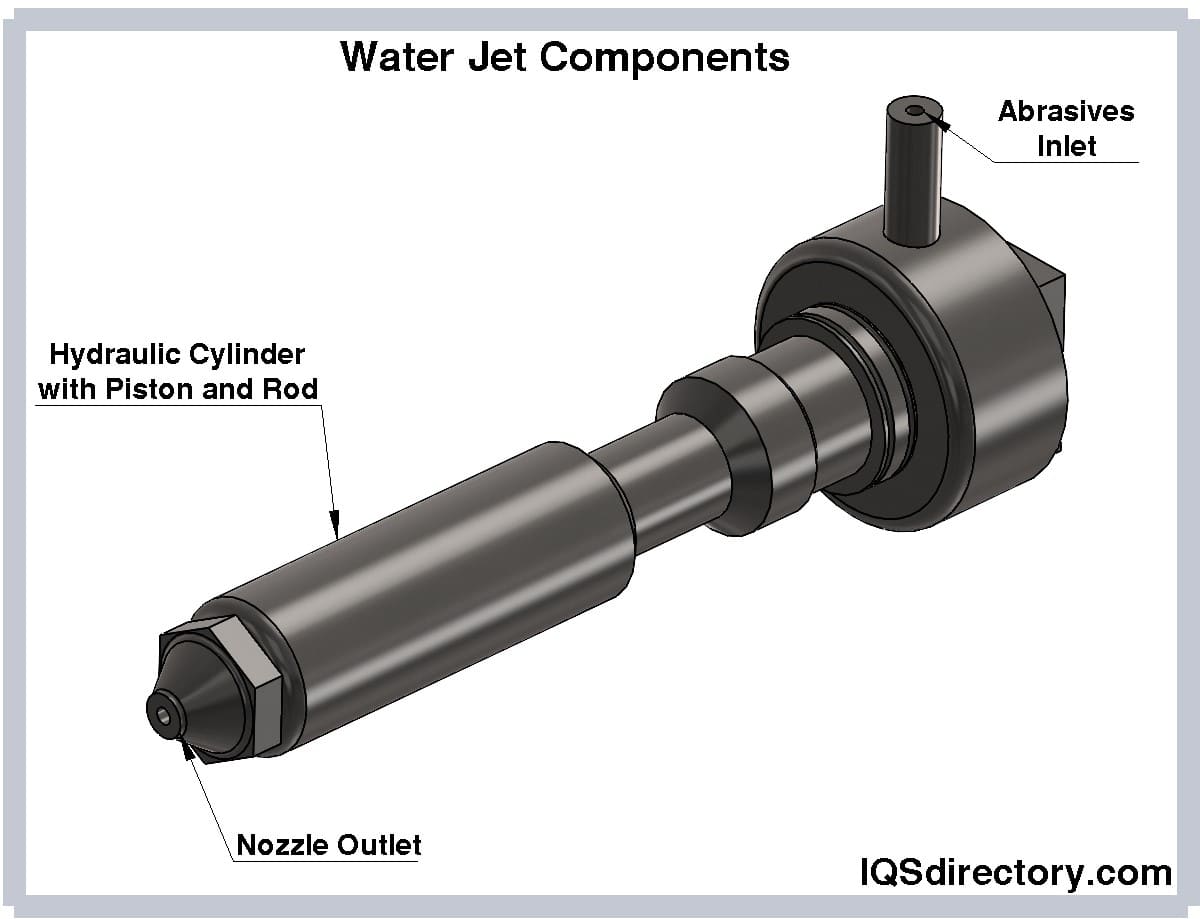

Nozzle

It is a tool used in water jet machining to transform the pressure energy of water into kinetic energy. The nozzle transforms the water jet's pressure into a high-velocity beam. The tip is constructed of diamond or ruby to prevent nozzle erosion.

Drain and Catcher System

With the aid of the drain and catcher system, the debris and machined particles from the water are separated after the machining.

Water Jet Cuts Types

Single Dimension

Water jet cuts made in one dimension are stationary cuts created while the workpiece passes through the water jet cutting device. They are used for trimming and are the most basic type of cut. While the debris and water are captured on the other side, the operator feeds the workpiece into the cutting tool. A slitter, which divides pieces into predetermined widths, is a version of the one-dimensional cutter. Water alone or mixed with an abrasive can be used as one-dimensional cutters.

XY in Two Dimensions

PC or CNC programming is required for two-dimensional cutting. They have a closed-loop feedback servo motor to regulate cutting speed and placement. Catcher tanks support the workpiece with slats and are filled with water. An XY two-dimensional cutting machine's Z section regulates the height of the cutting tool to accommodate variations in the workpiece's thickness. Cutting in two dimensions is best for quickly and accurately removing material from various items.

XYZ in Three Dimensions

The X-axis, which goes from left to right, the Y-axis, which moves from front to back, and the Z-axis, which moves up and down, are all used in three-dimensional cutting. In the three-axis process, the cutting tool moves along the three planes while the workpiece stays still. It is a method for creating mechanical parts.

XYZA in Four Dimensions

When cutting in four dimensions, the workpiece is treated along the three XYZ axes and in a fourth dimension by rotating around the X axis. The workpiece can be sliced along the B axis thanks to the A axis cutting. It is a great technique for creating holes or other apertures in the sides of a workpiece. With the A axis included, it is possible to automatically flip the workpiece so that the waterjet may remove material from both sides.

Advantages of Water Jet Machining

- It can cut materials without affecting their original structure. And the reason why this occurs is that there is no heat-affected zone (HAZ).

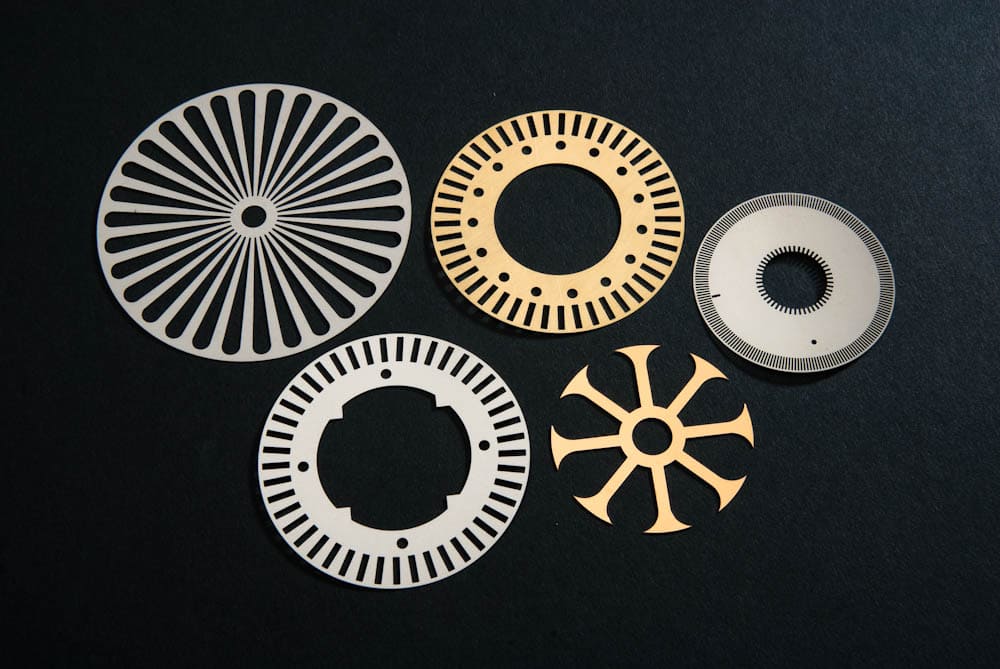

- It can cut materials with elaborate and complex patterns.

- During this machining process, the workspace is kept pristine and free of dust.

- Due to the limited need for moving parts, it requires little maintenance.

- Due to low heat generation, the workpiece suffers very little thermal damage.

- Both softer materials like rubber, plastic, or wood and tougher materials like granite can be cut with it; WJM for softer materials and AWJM for tougher materials.

- It is eco-friendly because it doesn't produce any hazardous waste or pollutants.

- The greater machining precision is present. It is simple to attain tolerances of an order of 0.005 inches.

Applications of Water Jet Cutting

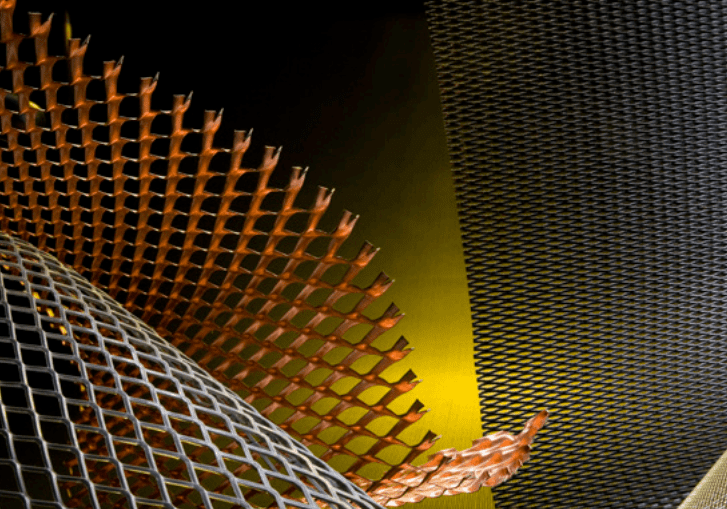

Water jet machining is employed in various industries, including mining, automotive, and aerospace, for cutting, shaping, and reaming operations. Rubber, textiles, plastics, foam, leather, composites, tile, stone, glass, food, metals, paper, and many more materials are commonly manufactured using water jet machining (WJM or AWJM).

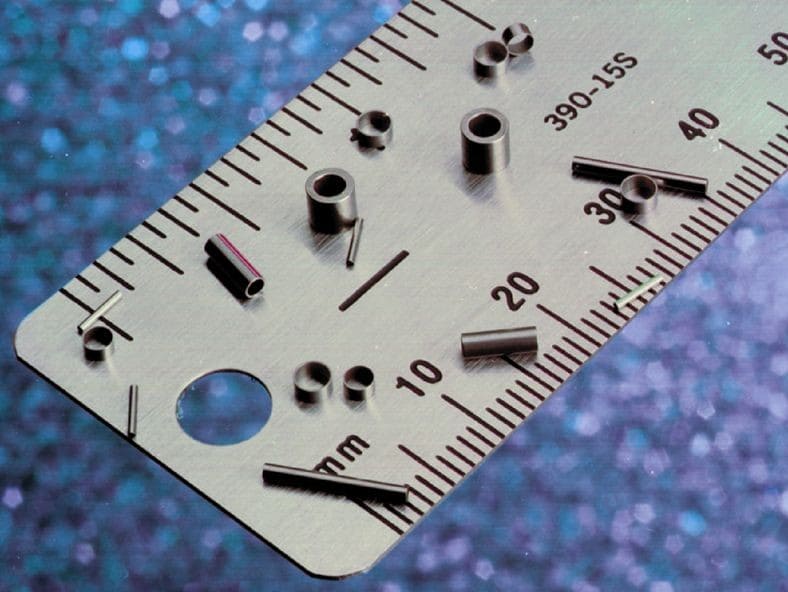

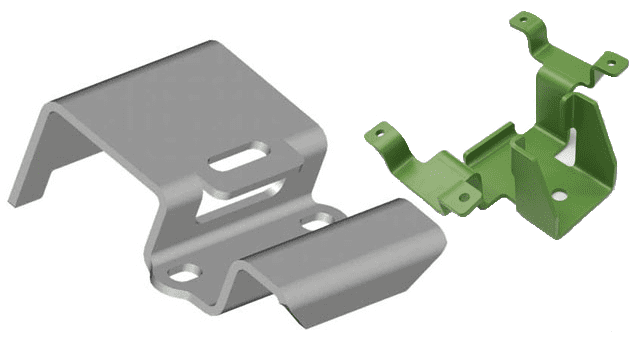

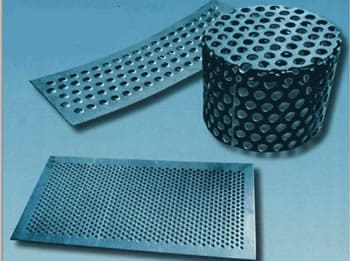

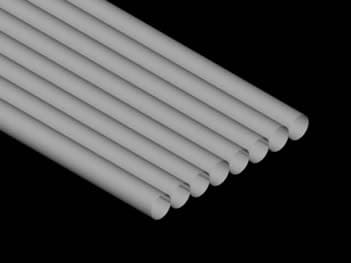

The primary applications for WJM are cutting soft and simple-to-machine materials, including thin sheets and foils, wood, non-ferrous metallic alloys, textiles, honeycomb, plastics, polymers, leathers, frozen food, etc. Hard and challenging-to-machine materials are often machined with AWJM. For example, it is used to cut thick plates made of steel, aluminum, and other industrial materials and reinforced polymers, multilayer composites, metal matrix, and ceramic matrix composites. The high-pressure water jet is also utilized in cleaning, surgery, peening to eliminate residual stress, and other processes aside from machining.

Choosing the Correct Water Jet Machining Company

To make sure you have the most productive outcome when selecting a water jet machining company, it is important to compare at least 4 water jet machiners using our list of water jet machining companies. Each water jet machining company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each water jet machining company website using our patented website preview to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple water jet machining companies with the same message.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services