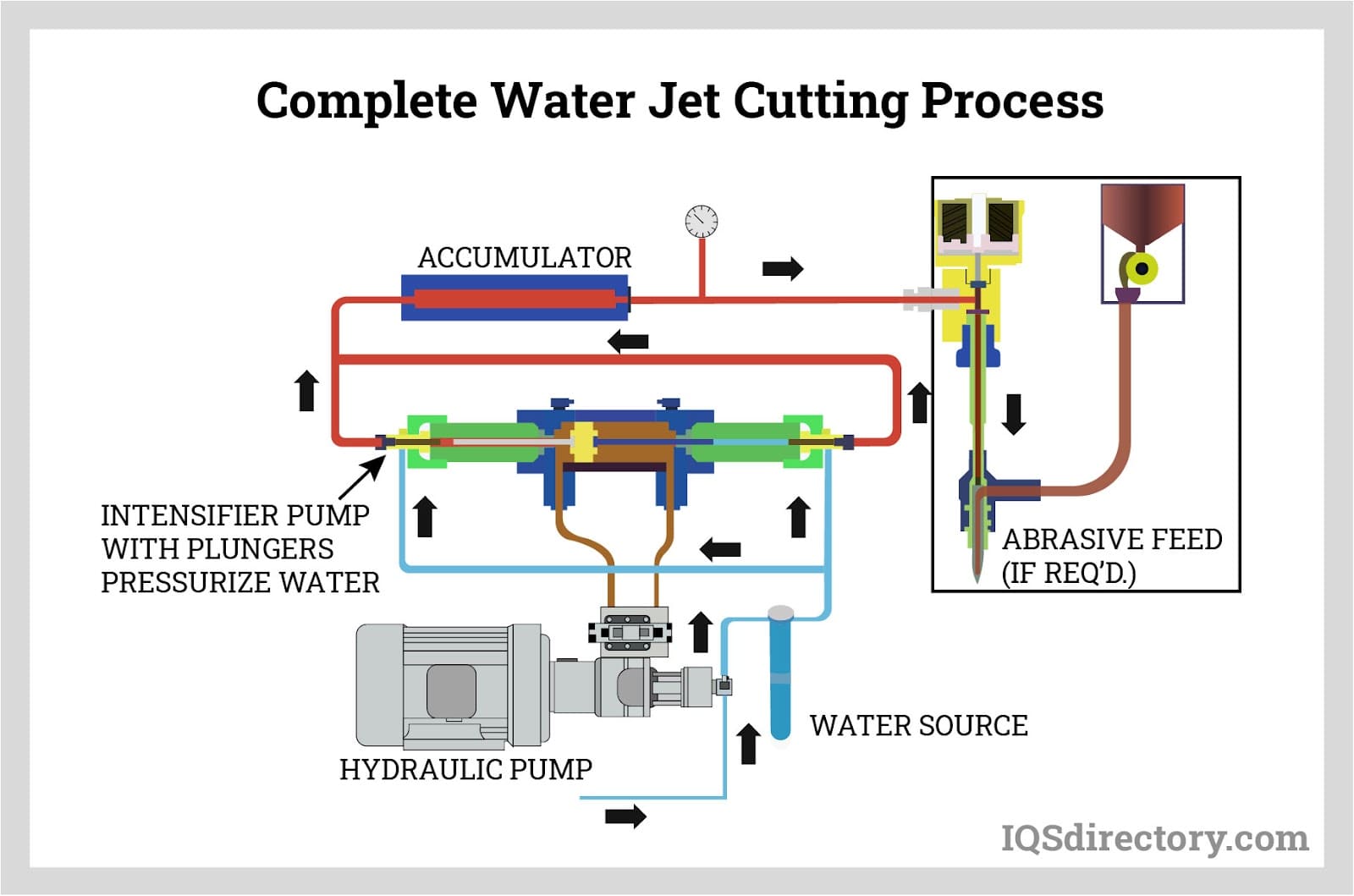

An engineering technique called water jet cutting uses the force of extremely fast, highly dense, and high-pressure water to cut objects. A small-bore nozzle (0.1 mm) with a maximum pressure of 392 MPa (or around 4,000 atmospheres) projects the water. A water jet with devastating force is created when water that has been compressed by an ultra high-pressure pump travels at a speed that is roughly three times the speed of sound. Read More…

MetPlas is your single source for cutting edge contract manufacturing. This ISO 9001-2008 registered manufacturer offers expertise in lean manufacturing & a wide range of precision machining, waterjet cutting & assembly of metals & plastics. OEM’s have relied on MetPlas for decades to meet their quality, schedule & budget needs. The logical choice for virtually any contract manufacturing...

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

As a full-service waterjet machining center, RTD Manufacturing uses waterjet cutting in the manufacture of our products. Besides waterjet cutting, we also use EDM wire cutting; detail and manual machining; CNC machining plus production drill and tap. We have prototype manufacturing to offer as well.

Arcadia operates one of the largest waterjet job shops in the eastern U.S., manufacturing custom-cut parts and shapes for a variety of industries. We provide waterjet cutting services using large capacities and 5-axis water jet machining. Allow our experience to improve your manufacturing process.

We provide top of the line water jet cutting here at West Coast Waterjet. We are ISO 9001:2008 certified and our experts have a wide experience of waterjet cutting for a wide variety of industries. Our services are for virtually any material and we will work with you every step of the way. Please give us a call today to learn more information!

More Water Jet Metal Cutting Companies

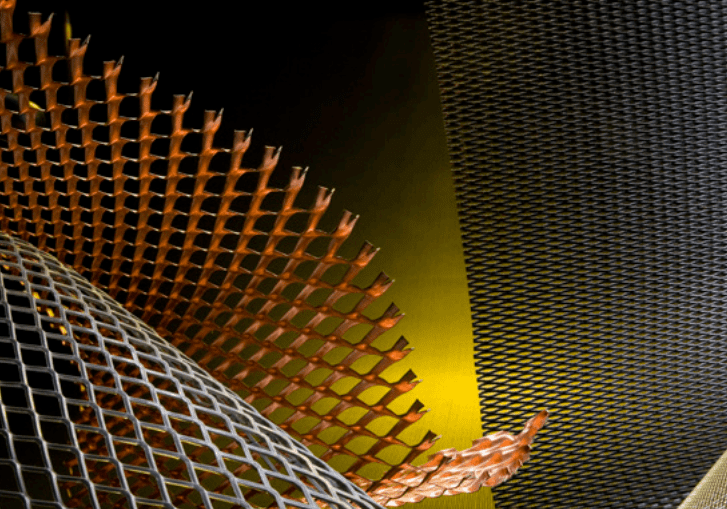

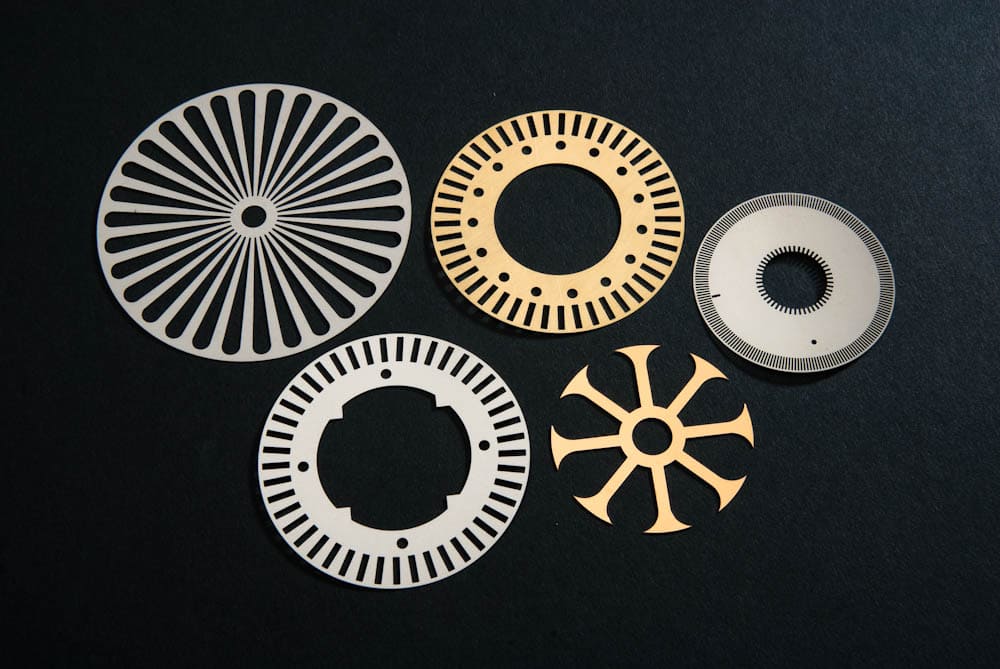

For example, water jet cutting is used to effectively cut shapes and parts in the aerospace and automotive industries. A granular abrasive is supplied to the water jet to strengthen the cutting force when cutting extremely hard materials.

How Water Jet Cutting is performed

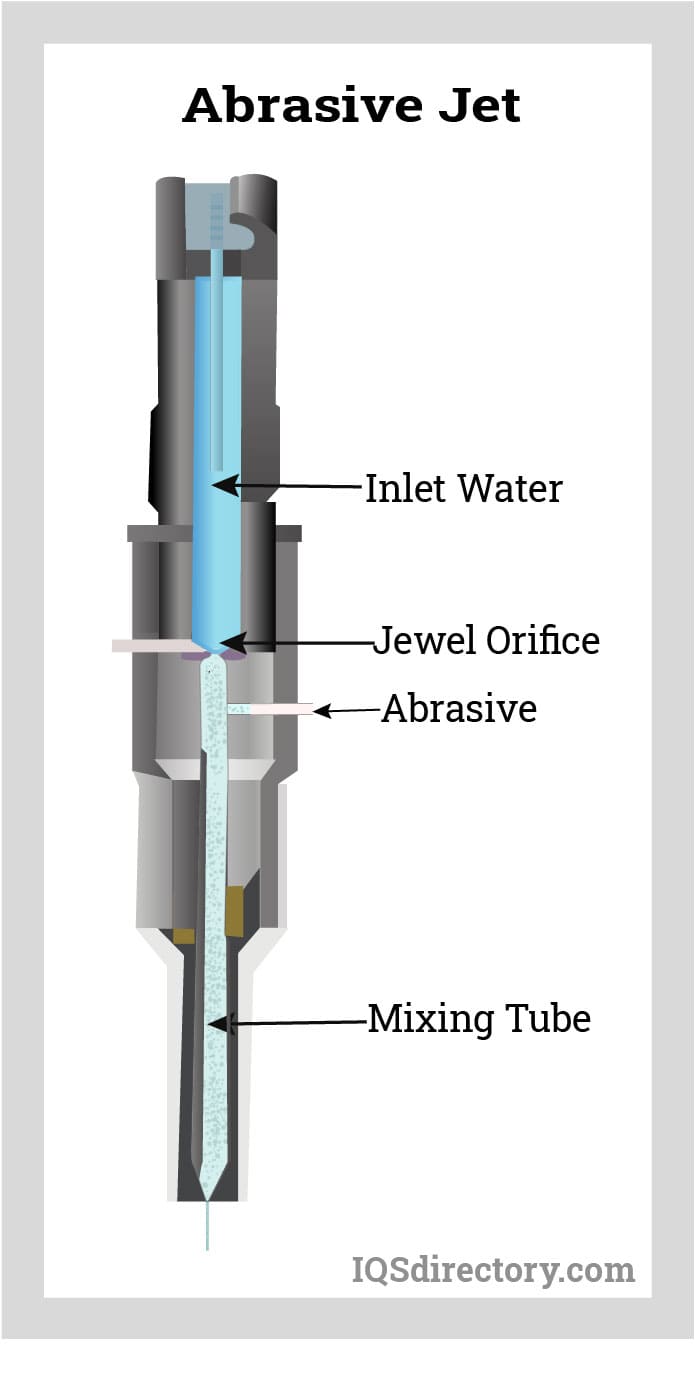

Water jet cutting occurs either as abrasive or pure water jet cutting.

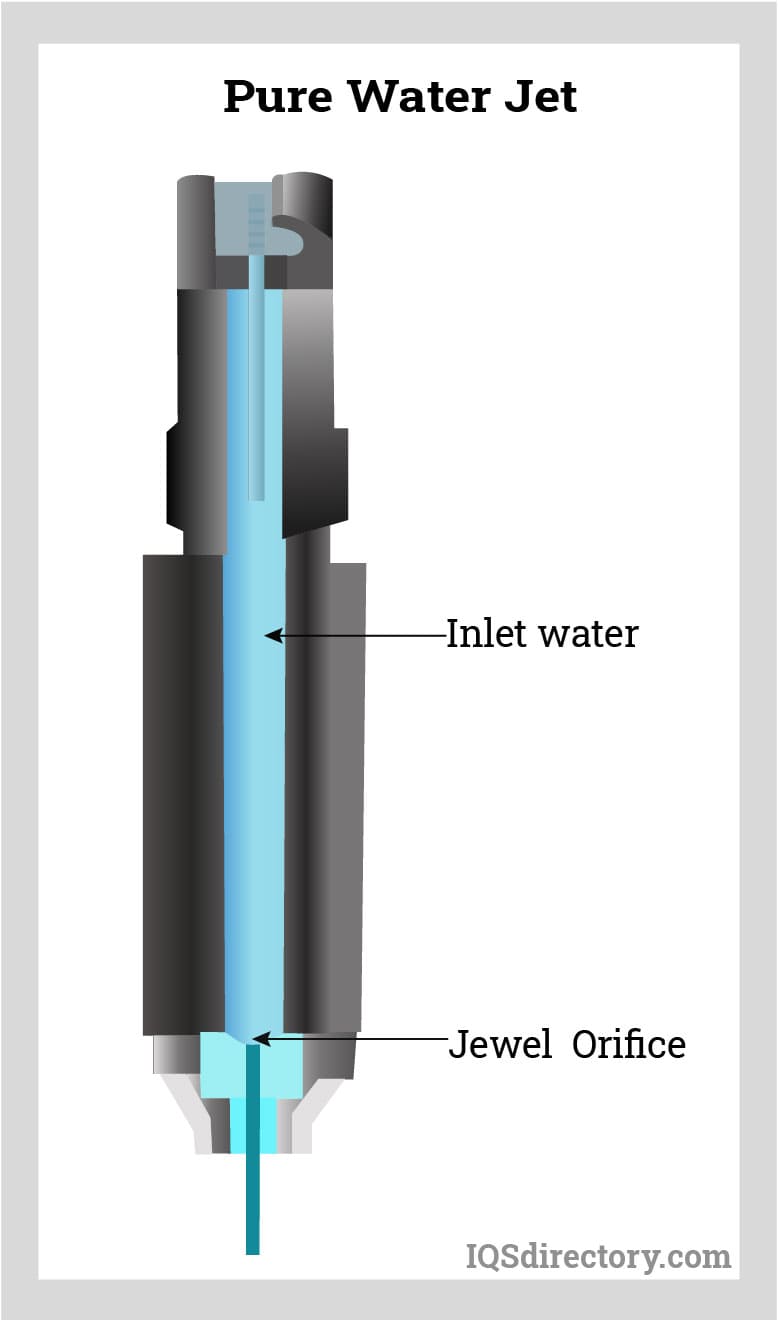

Pure Water Jet Cutting

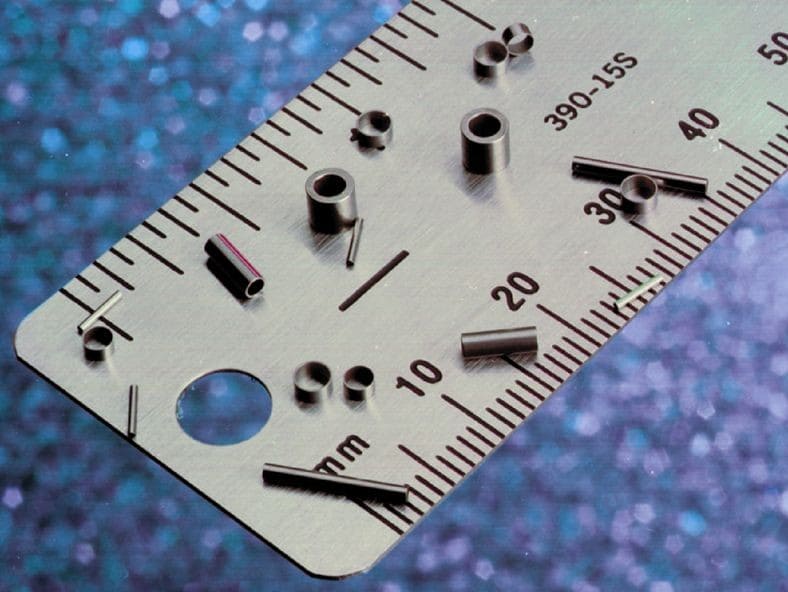

Soft metals like aluminum can also be cut using the pure water jet cutting method. Pure water jet cutting doesn’t use abrasive material, making it better to cut softer metals like aluminum. In this instance, the water penetrates the material under its pressure and velocity. The streams are exceedingly thin, ranging in diameter from 0.004 to 0.010 inches, and they offer incredible precision with minimal material loss. Cutting forces are quite modest, and fixturing is frequently straightforward. These devices work best when used around-the-clock. It is crucial to understand the stream’s velocity, not pressure, erodes small granules of material. To reach a high velocity, pressurized water travels through a tiny hole in a jewel attached to the end of the nozzle, usually a sapphire, ruby, or diamond.

Abrasive Water Jet Cutting

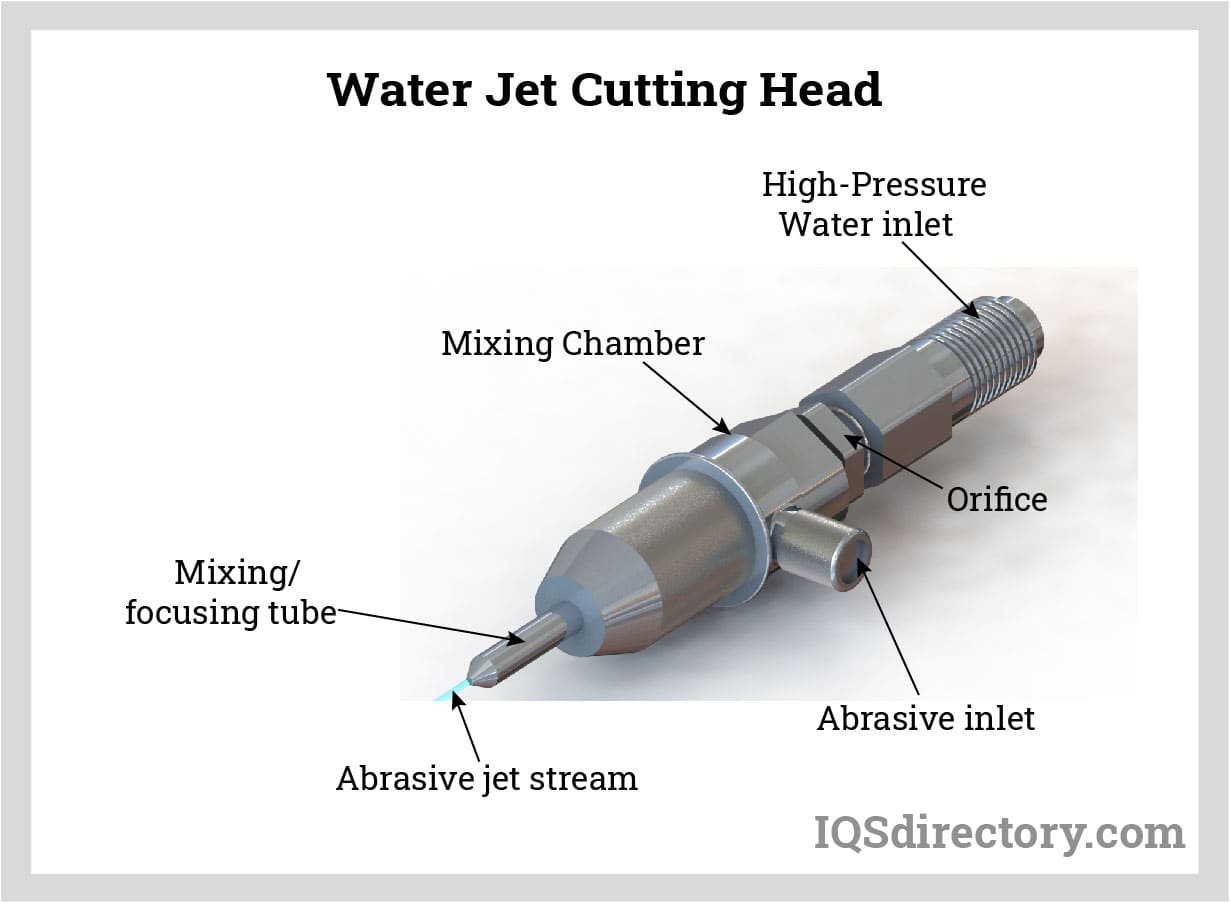

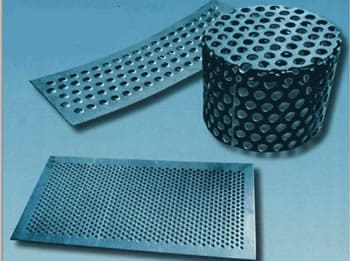

Water jet cutting uses abrasives such as aluminum oxide or garnet. Abrasive media is introduced to the water stream from a small mixing chamber inside the cutting head. Added abrasives make it possible to cut Ceramics, metals, stones, and thick polymers with water jet cutters. However, refrain from using abrasive water to cut glass and diamonds. glass will shatter under an abrasive water jet cutter.

The abrasive particles do most of the material removal. Abrasive streams have a diameter of between 0.020 inch and 0.050 inch, making them bigger than their pure water jet cousins. They can cut materials and stacks up to 10 inches thick without producing any mechanical strains or heat-affected zones. Cutting forces for abrasive streams are still less than one pound despite their increasing strength. Almost all abrasive jet tasks employ a single jet setup, and switching from a single to several heads or even from abrasive to pure water jet is simple.

Advantages of Water Jet Cutting

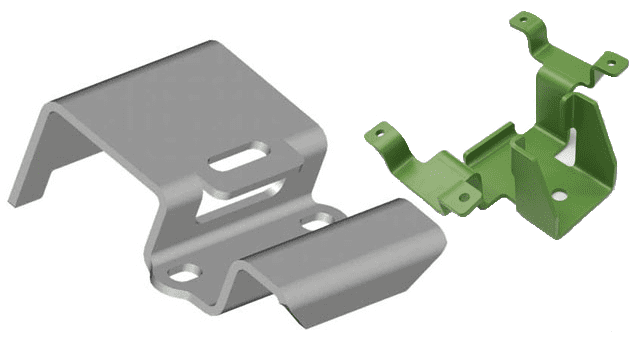

- No other cutting technique can compete with the superior quality parts produced by water jet cutting. The edges don't require debarring because they are smooth. Cutting speed, pressure, abrasive flow rate, and nozzle size are only a few of the variables that affect the final product's quality. For the best results, the process settings might need to be changed.

- High cutting accuracy is a benefit of water jet cutting. Even when constrained by strict standards, water jet cut parts are of exceptionally good quality. This is beneficial when fabricating metal products because it ensures we get the perfect final product.

- Due to the cold cutting technology used in waterjet cutting, there is no heat-impacted zone (HAZ). As a result, cold cutting makes clean cuts possible and greatly improves operator safety by lowering the possibility of burns.

- No material distortion: The cold cutting technique avoids heat exposure, which is crucial for materials like metal. This results in a fine cut without material distortion. In addition, this produces a clean, burr-free cut.

- There is no additional finishing step: An additional finishing process is avoided because of the initial high-cutting quality that guarantees a precise output. This greatly shortens the cutting process and saves time, improving efficiency.

Choosing the Proper Waterjet Metal Cutting Company

To make sure you have the most positive outcome when selecting a waterjet metal cutting company, it is important to compare at least 5 waterjet metal cutting companies using our waterjet metal cutting directory. Each waterjet metal cutter has a business profile page that highlights their area of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each waterjet metal cutting business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple waterjet metal cutter companies with the same quote.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services