Water jet cutting machinery uses water under high pressure and velocity to precisely cut through material. Read More…

MetPlas is your single source for cutting edge contract manufacturing. This ISO 9001-2008 registered manufacturer offers expertise in lean manufacturing & a wide range of precision machining, waterjet cutting & assembly of metals & plastics. OEM’s have relied on MetPlas for decades to meet their quality, schedule & budget needs. The logical choice for virtually any contract manufacturing...

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

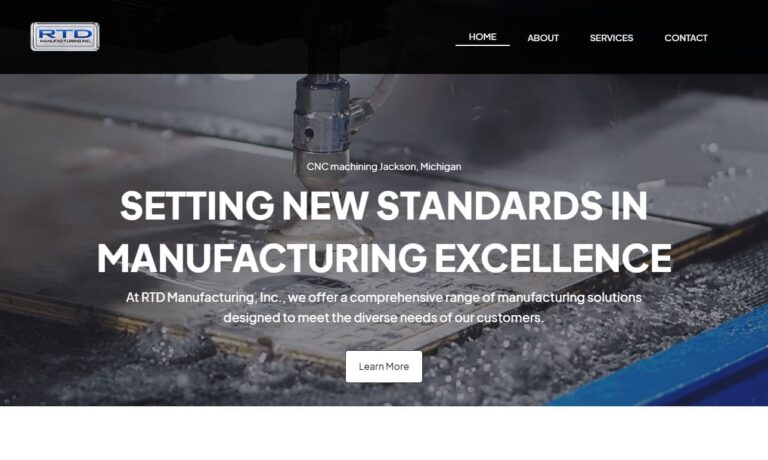

As a full-service waterjet machining center, RTD Manufacturing uses waterjet cutting in the manufacture of our products. Besides waterjet cutting, we also use EDM wire cutting; detail and manual machining; CNC machining plus production drill and tap. We have prototype manufacturing to offer as well.

Arcadia operates one of the largest waterjet job shops in the eastern U.S., manufacturing custom-cut parts and shapes for a variety of industries. We provide waterjet cutting services using large capacities and 5-axis water jet machining. Allow our experience to improve your manufacturing process.

We provide top of the line water jet cutting here at West Coast Waterjet. We are ISO 9001:2008 certified and our experts have a wide experience of waterjet cutting for a wide variety of industries. Our services are for virtually any material and we will work with you every step of the way. Please give us a call today to learn more information!

More Waterjet Cutting Machinery Companies

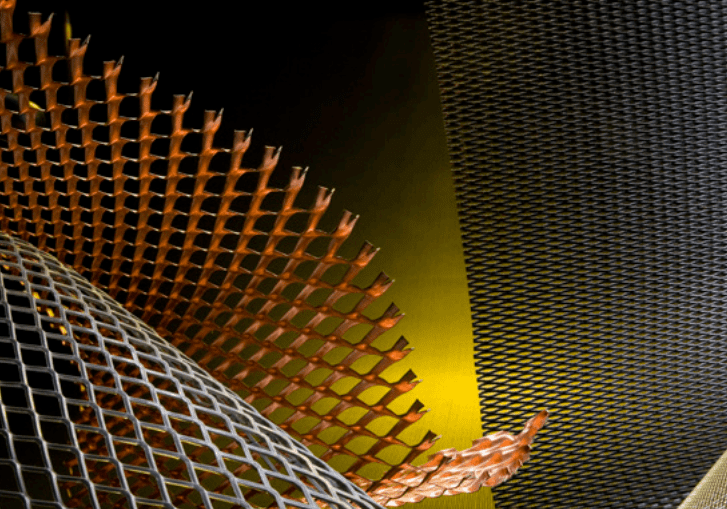

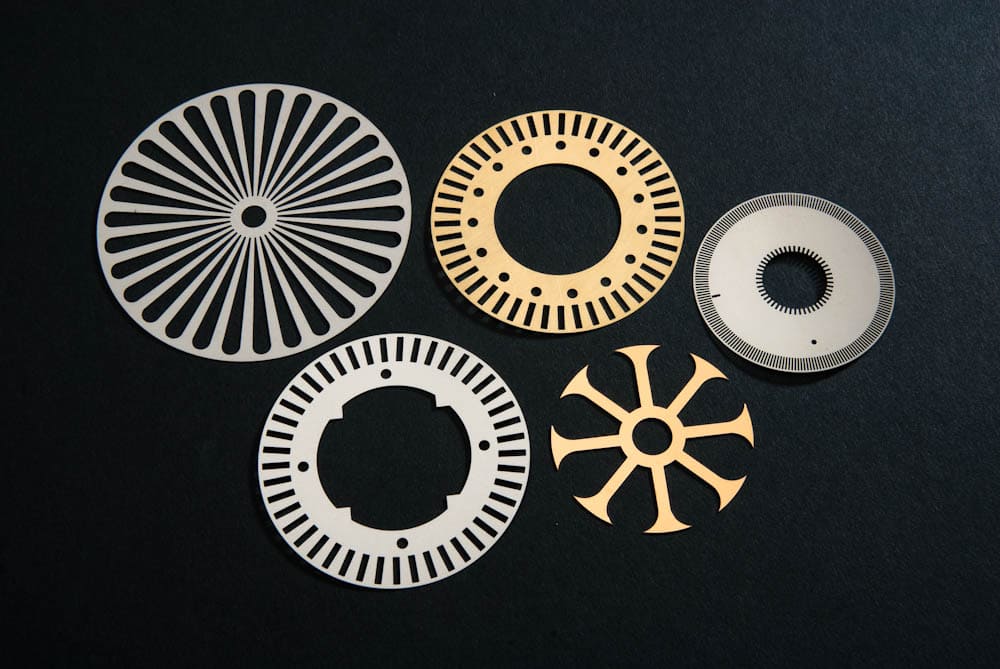

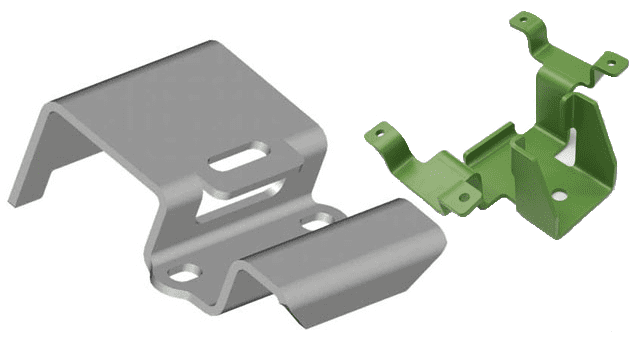

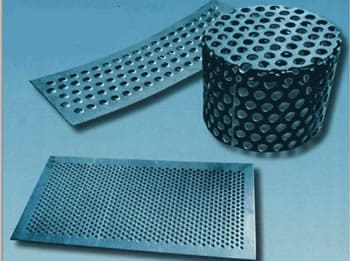

Many kinds of metal, some kinds of glass, a few kinds a ceramics and a variety of other materials can be cut by water jet cutters. A water jet cutter creates metal shapes by spraying a concentrated stream of water at a work piece.

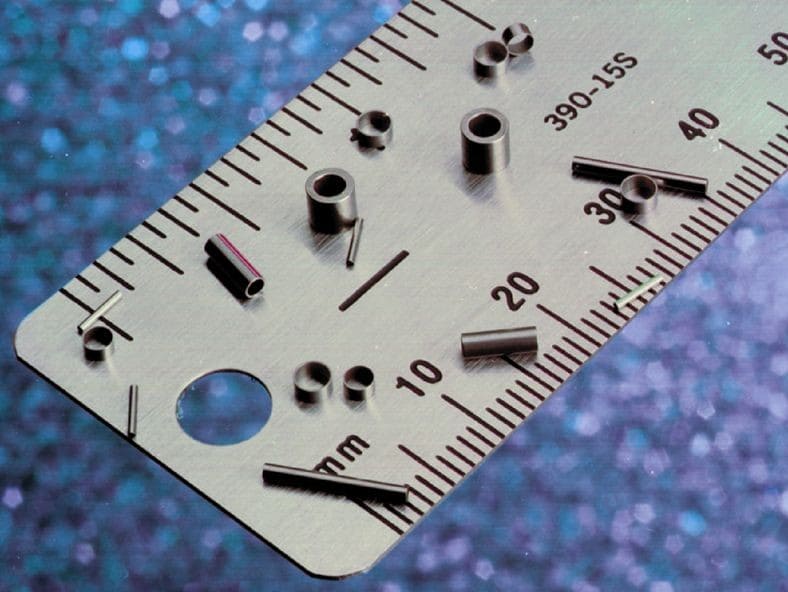

Most water jet cutting work pieces are thin sheets out of which flat shapes are cut, though gears and other complex shapes can also be cut by water jets. Depending on the equipment, a water jet cutter can deliver water streams at pressures anywhere between 30,000 and 90,000 PSI. The higher-pressure models are used in high pressure water jet cutting, which is used in the cutting of very strong work pieces. Water jet cutting engineers choose water pressures depending on the qualities of the work pieces. Brittle or shatter-prone materials like glass, for example, are cut with lower-pressure streams to prevent breakage. Very strong metals like titanium or steel are more likely to be cut with streams at much higher pressures, and abrasive media may be added to the water stream to improve cutting efficiency. Because almost every water jet cutting process is managed by computer numerical control (CNC), products emerging from water jet processing are sure to bear a near-perfect resemblance to their technical drawings.

In addition to producing products with extreme precision, water jet cutting machinery systems are highly efficient and safe alternatives to other cutting processes. Laser cutting, another popular cutting process, is also very precise and can be fully automated. However, it generates heat, sparks and fumes that can pose health and safety hazards to workers. It can also be extremely energy-intensive and inefficient. Water jet cutting’s efficiency is due in large part to its reclamation system; all of the water and abrasive media expelled during the process can be collected and recycled, greatly reducing the consumption of water and abrasives. Also, compared to other cutting processes that involve heat, blades or other potentially hazardous equipment or conditions, water jet cutting is safe and requires few accommodations for worker safety, as no workers are near the water jet during its operation. The major occupational hazard to consider in water jet cutting processes is noise, as the process can be very loud; a combination of personal ear protection and soundproofing can easily reduce that risk to workers.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

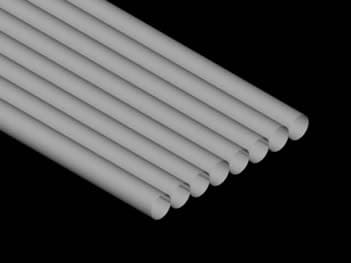

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services