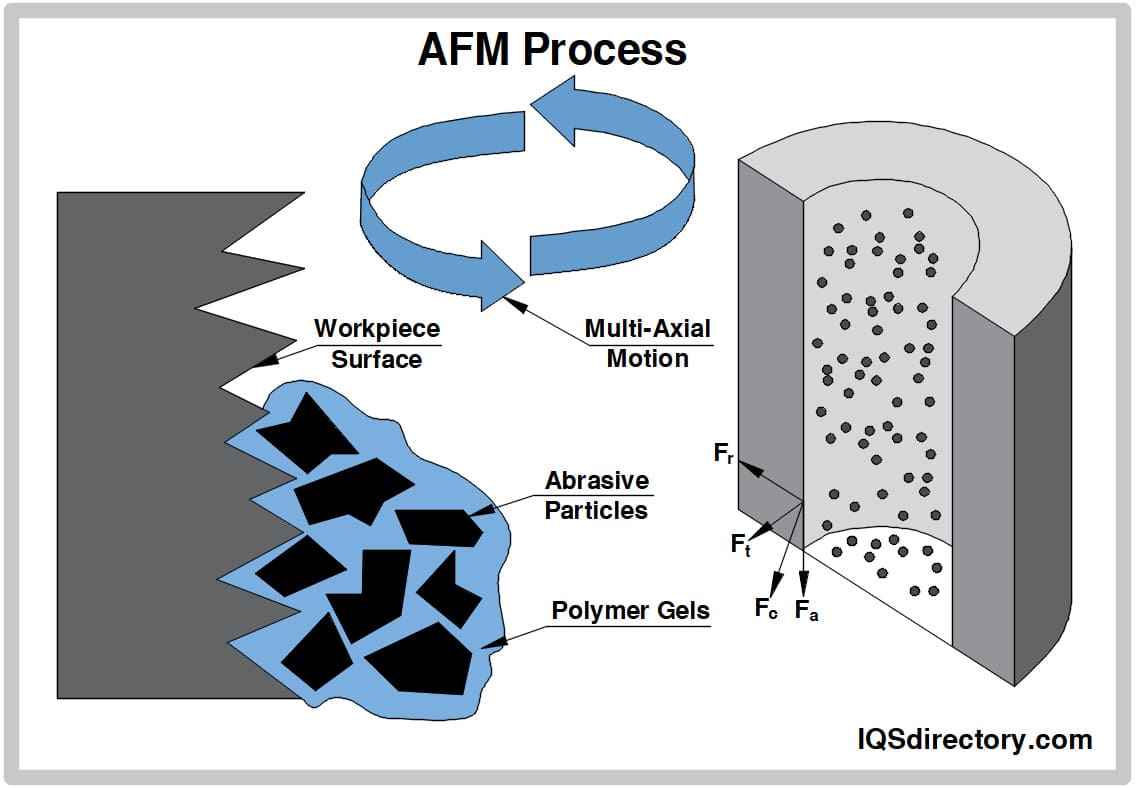

AFM, often referred to as abrasive flow deburring or extrusion honing, is a method of internal surface finishing that involves passing an abrasive fluid through a work piece. Abrasive flow machining forces a semi-liquid, abrasive material through or over a workpiece to polish surfaces and edges. Only in areas where the media flow is restricted does abrasion occur; other regions are unaffected. It can simultaneously process many chosen sections on a work piece, including unreachable locations. Read More…

MetPlas is your single source for cutting edge contract manufacturing. This ISO 9001-2008 registered manufacturer offers expertise in lean manufacturing & a wide range of precision machining, waterjet cutting & assembly of metals & plastics. OEM’s have relied on MetPlas for decades to meet their quality, schedule & budget needs. The logical choice for virtually any contract manufacturing...

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

As a full-service waterjet machining center, RTD Manufacturing uses waterjet cutting in the manufacture of our products. Besides waterjet cutting, we also use EDM wire cutting; detail and manual machining; CNC machining plus production drill and tap. We have prototype manufacturing to offer as well.

Arcadia operates one of the largest waterjet job shops in the eastern U.S., manufacturing custom-cut parts and shapes for a variety of industries. We provide waterjet cutting services using large capacities and 5-axis water jet machining. Allow our experience to improve your manufacturing process.

We provide top of the line water jet cutting here at West Coast Waterjet. We are ISO 9001:2008 certified and our experts have a wide experience of waterjet cutting for a wide variety of industries. Our services are for virtually any material and we will work with you every step of the way. Please give us a call today to learn more information!

More Abrasive Flow Machining Companies

One fixture can process several or even dozens of pieces, resulting in production speeds of up to hundreds of parts per hour. Changing the process parameters produces different outcomes. Even in production settings, tooling can be created so that it can be modified in a matter of minutes. The surface finishes produced by the AFM method often improve by 90%, and stock removal may be controlled to within 10% of the stock removed.

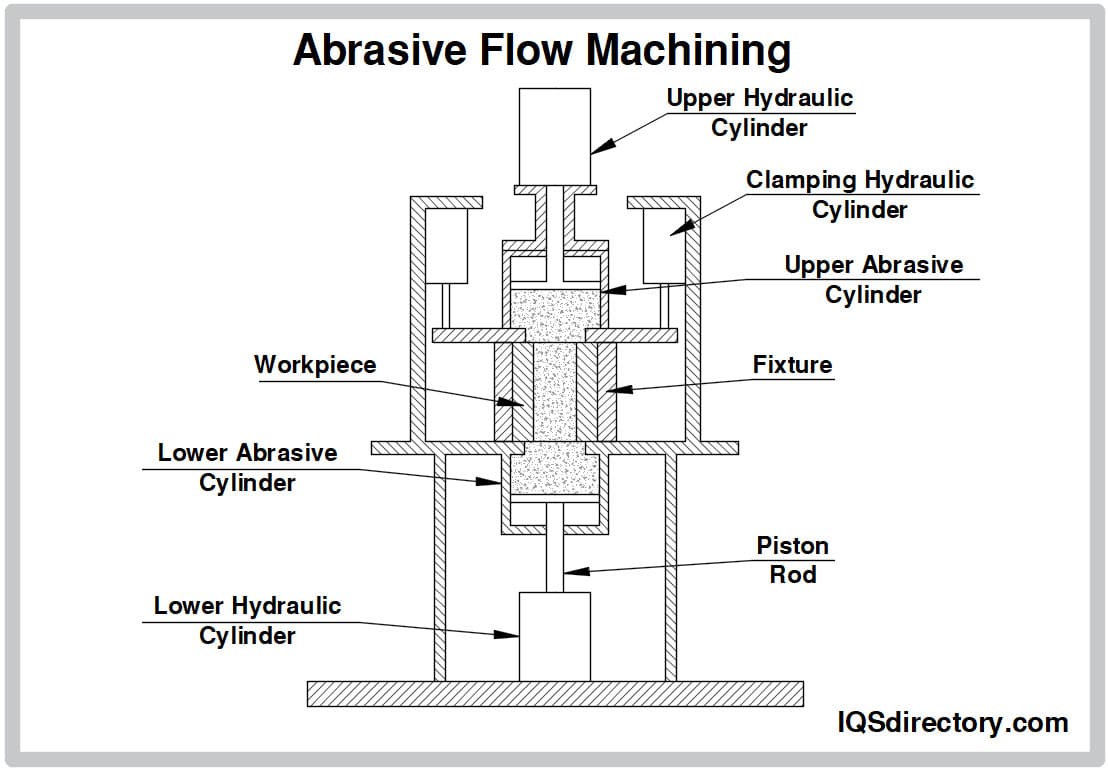

How Abrasive Flow Machining Works

The abrasive-filled fluid runs through the item during the extrusion honing procedure to erode it. The elevated features on the surface are removed as it comes into contact with the abrasive fluid, similar to how sandpaper removes wood splinters. Hydraulics push the fluid through during the process. No areas are overlooked since the putty-like material may mold itself to the exact shape of the item chamber. Abrasive Flow Machining can be used as a two- or one-way flow technique.

A semisolid abrasive media is extruded back and forth through passageways created by the work piece. The process is abrasive only in the extrusion area, where the flow is constrained. The abrasive media gently and uniformly hones the surface or edges, simulating a grinding or lapping procedure. This technique helps shape materials ranging from soft aluminum to strong nickel alloys, ceramics, and carbides.

Applications of Abrasive Flow Machining

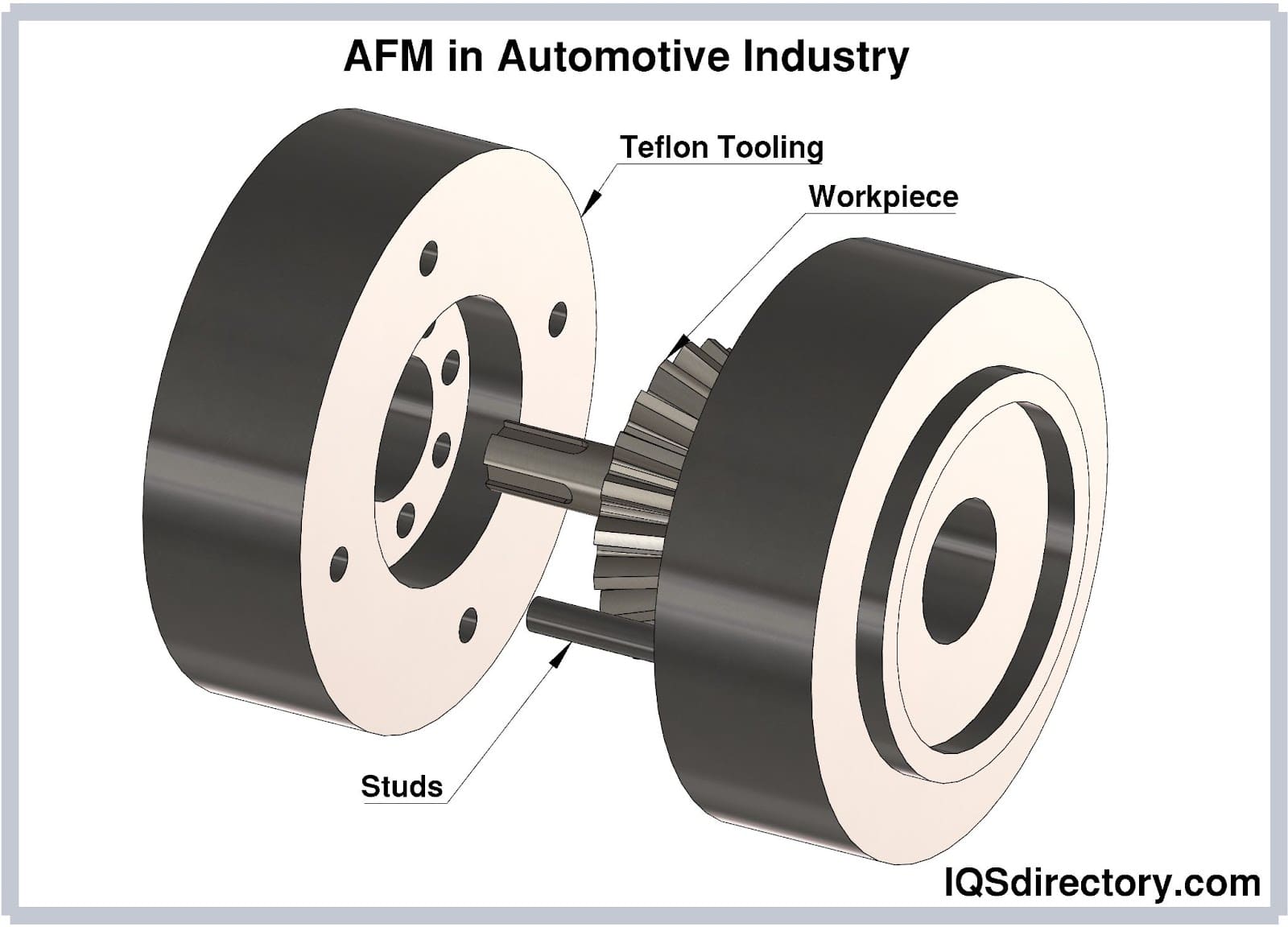

- AFM is used in the automotive Industry to enhance uniformity and surface quality of finished products. The automotive industry often uses radiusing -a method of creating a consistent radius for rounded edges. AFM also helps polish engine parts to increase efficiency and reduces emissions.

- The aerospace industry uses AFM to improve the texture of products. This increases cycle fatigue strength.

- The die and mold industry uses AFM to lower production costs while maintaining uniform and quality products.

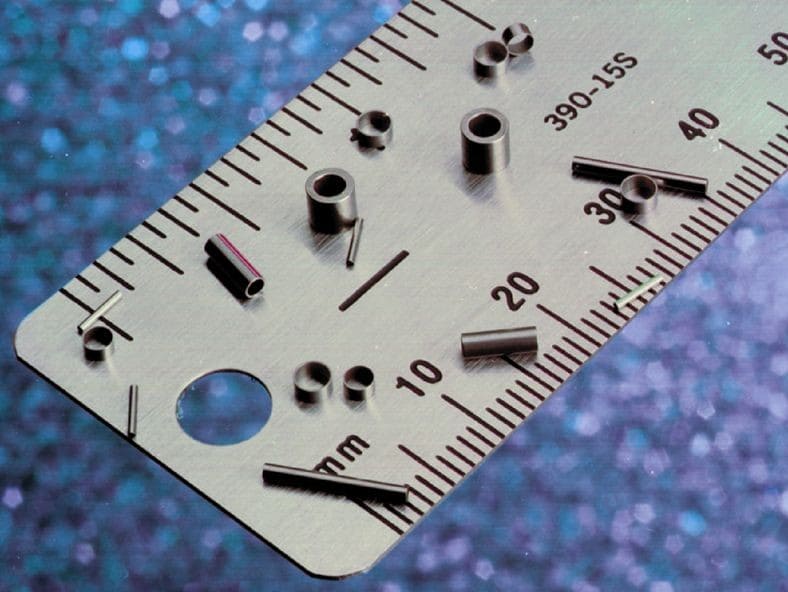

- The AFM process is also used in the medical industry through deburring. Deburring removes extra material from components that have been cut, drilled, or burred. This is crucial for objects like needles and cannulas that are injected into people.

Benefits of Abrasive Flow Machining

- Versatility: Any metal, including titanium, super alloys, and materials that have been hardened or are otherwise challenging to mill, can be processed using AFM.

- Precision: Targeted and challenging spots, such as cross-drilled and intersecting holes, can be emptied of component material by AFM.

- Efficiency: A single pass can finish the roughing and finishing of the workpiece.

- Customizability: The abrasive media can be developed to meet the demands of a given application.

- Consistency: Technique control offered by the AFM process ensures excellent reproducibility and constant quality.

Drawbacks of abrasive flow machining

- The process is very expensive and is also not usable on soft or ductile products

- Processing of blind holes is very complex

Choosing the Proper Abrasive Flow Machining Company

To make sure you have the most beneficial outcome when selecting an abrasive flow machining company, it is important to compare at least 5 companies using our abrasive flow machining directory. Each abrasive flow machining company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each abrasive flow machining company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple abrasive flow machining companies with the same message.

Broaching

Broaching CNC Machining

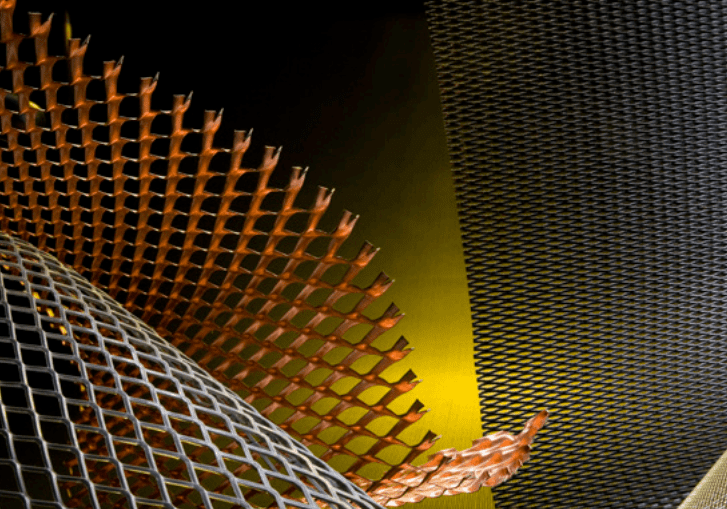

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

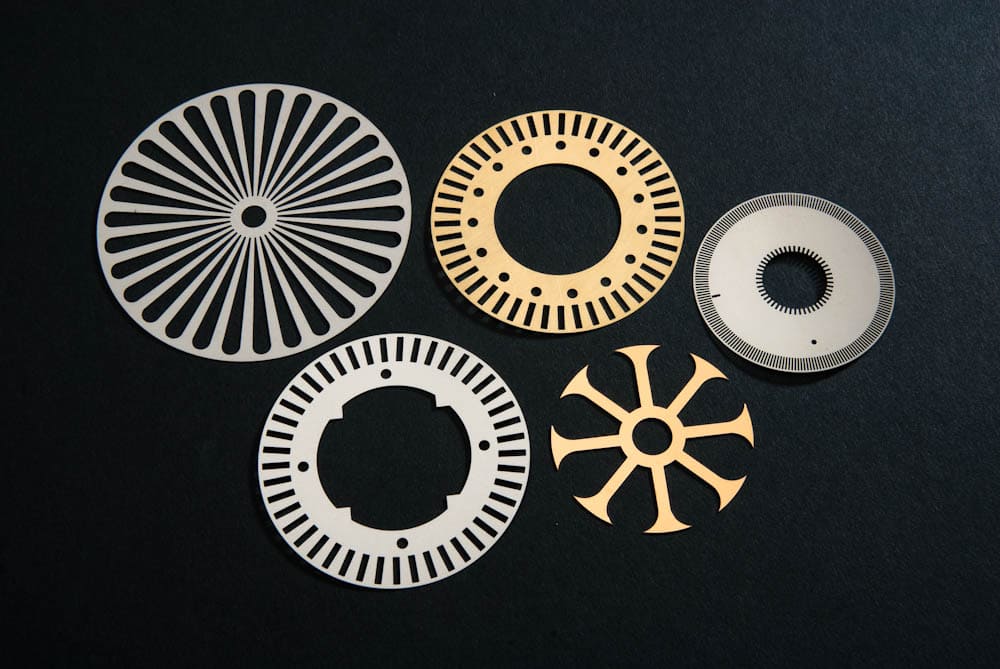

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

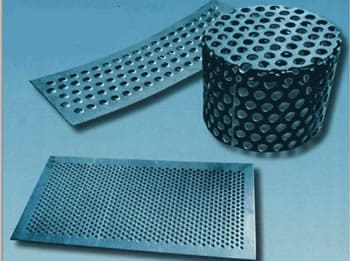

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

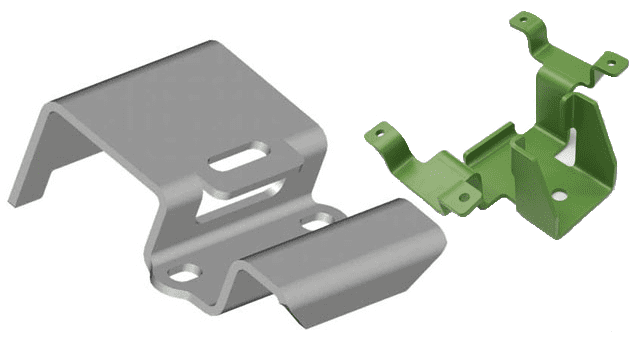

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services