For applications like this, the water is mixed with abrasive particles made of garnet or diamond. As well, machines sometimes use high pressure jets to cut through hard substances. Read More…

MetPlas is your single source for cutting edge contract manufacturing. This ISO 9001-2008 registered manufacturer offers expertise in lean manufacturing & a wide range of precision machining, waterjet cutting & assembly of metals & plastics. OEM’s have relied on MetPlas for decades to meet their quality, schedule & budget needs. The logical choice for virtually any contract manufacturing...

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

As a full-service waterjet machining center, RTD Manufacturing uses waterjet cutting in the manufacture of our products. Besides waterjet cutting, we also use EDM wire cutting; detail and manual machining; CNC machining plus production drill and tap. We have prototype manufacturing to offer as well.

Arcadia operates one of the largest waterjet job shops in the eastern U.S., manufacturing custom-cut parts and shapes for a variety of industries. We provide waterjet cutting services using large capacities and 5-axis water jet machining. Allow our experience to improve your manufacturing process.

We provide top of the line water jet cutting here at West Coast Waterjet. We are ISO 9001:2008 certified and our experts have a wide experience of waterjet cutting for a wide variety of industries. Our services are for virtually any material and we will work with you every step of the way. Please give us a call today to learn more information!

More High Pressure Water Cutting Companies

Standard water jets have a constant stream of water that shoots out at pressures between 30,000 to 90,000 PSI. Some high pressure water cutters, however, have nozzles with jets as strong as 120,000 PSI, which propel water at twice the speed of sound. It also increases cutting speeds by up to 20 percent, thus quickening output times, which is important for applications where repeatability and mass production are applied.

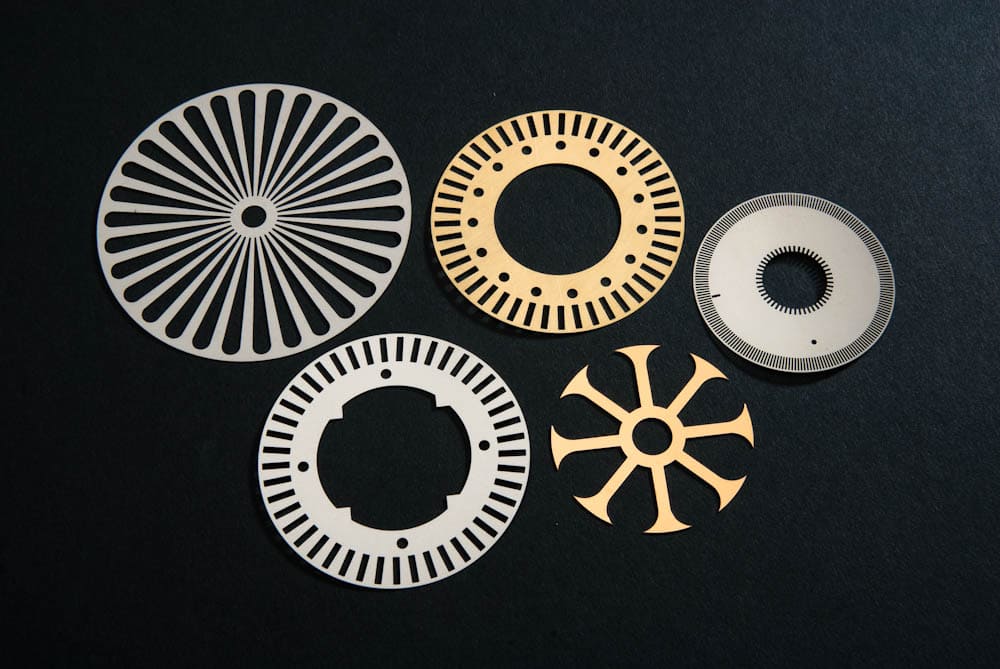

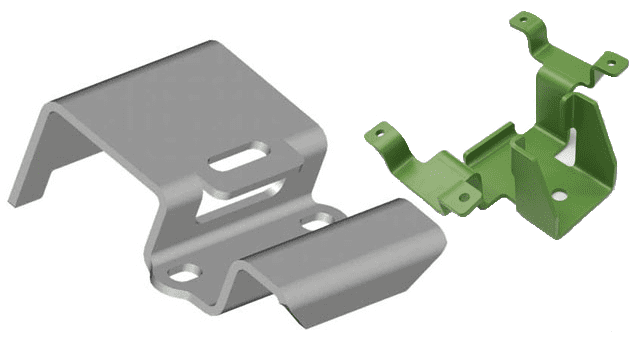

Using high pressure in combination with abrasive particles to cut harder materials is a popular alternative to plasma cutting, sawing and welding. It produces a clean, smooth cut with no rough edges or burrs. Modern machines are fully automated and use CNC (computer numerical controlled) software that allows for high precision, accuracy and detail.

Assigning a computer to control a water jet cutting process not only ensures high levels of manufacturing precision, but it also reduces labor costs. Technical staff are only necessary for the setup, programming, monitoring and repair of equipment in many cases.

High pressure water cutting machines, which are referred to as ultra high pressure water jet cutters, obtain such high pressures by using intensifiers, which are pumps that use hydraulics to create extremely high pressure. Hydraulic systems harness the power of water moving at a fast pace and convert it to mechanical energy. To quicken the rate of the cutting process, many water jet cutters use multiple cutting heads. Most high pressure cutting machines have the ability to switch back and fourth between standard and high powered operation levels.

For those that operate mainly on ultra high pressure, cylinders and end caps are not threaded, which prevents the formation of cracks. The intensifier pumps use hydraulic accumulators that reduce wear and tougher center sections, piston seals and wear rings, which increase the machine's lifespan and reduce the probability of leaking. High pressure machines tend to be much louder than standard water jet cutters, and are often equipped with a soundproof casing.

Broaching

Broaching CNC Machining

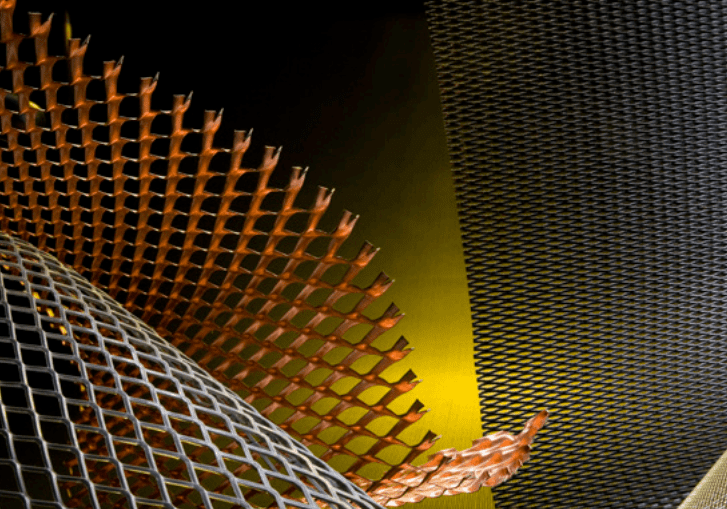

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

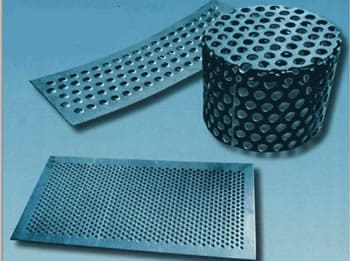

Metal Fabrication Perforated Metals

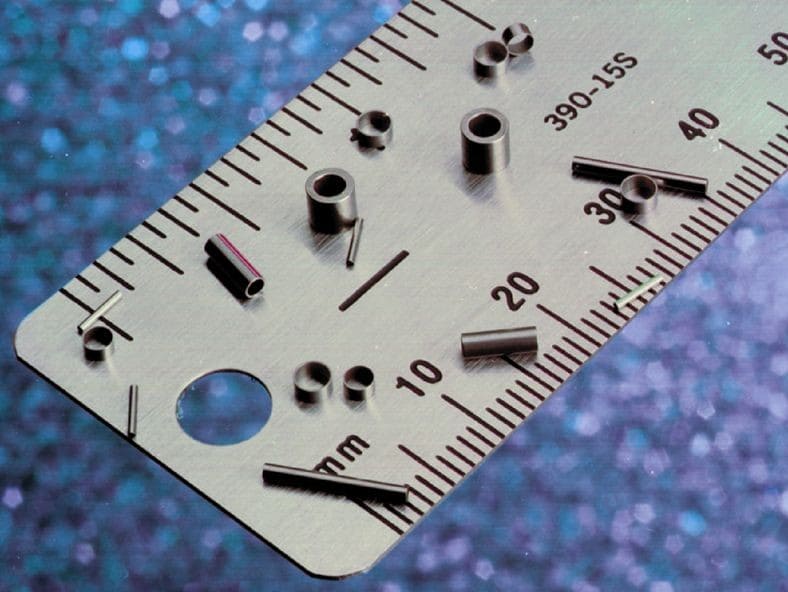

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services