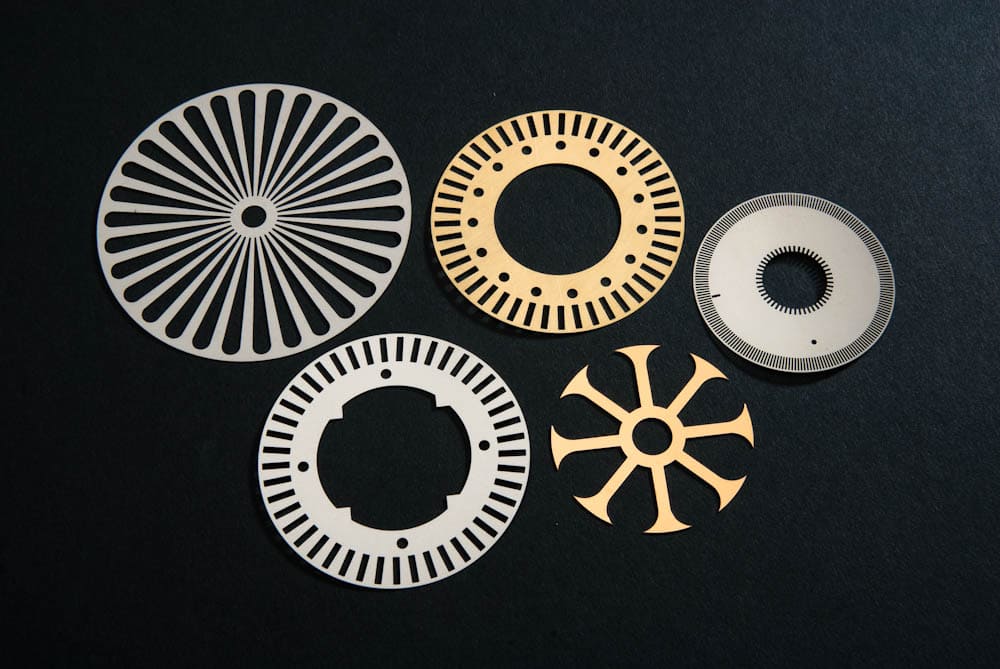

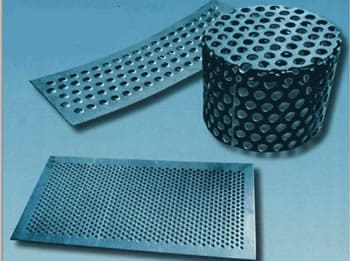

Flat or semi-flat materials like metal, glass, plastic, foam, marble, stone and wood are cut using either pure water or, in the case of abrasive water jet cutting, water mixed with abrasive particles like garnet or diamond for added strength; abrasive media are usually added for use on tougher materials. Read More…

MetPlas is your single source for cutting edge contract manufacturing. This ISO 9001-2008 registered manufacturer offers expertise in lean manufacturing & a wide range of precision machining, waterjet cutting & assembly of metals & plastics. OEM’s have relied on MetPlas for decades to meet their quality, schedule & budget needs. The logical choice for virtually any contract manufacturing...

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

As a full-service waterjet machining center, RTD Manufacturing uses waterjet cutting in the manufacture of our products. Besides waterjet cutting, we also use EDM wire cutting; detail and manual machining; CNC machining plus production drill and tap. We have prototype manufacturing to offer as well.

Arcadia operates one of the largest waterjet job shops in the eastern U.S., manufacturing custom-cut parts and shapes for a variety of industries. We provide waterjet cutting services using large capacities and 5-axis water jet machining. Allow our experience to improve your manufacturing process.

We provide top of the line water jet cutting here at West Coast Waterjet. We are ISO 9001:2008 certified and our experts have a wide experience of waterjet cutting for a wide variety of industries. Our services are for virtually any material and we will work with you every step of the way. Please give us a call today to learn more information!

More Hydro Cutting Companies

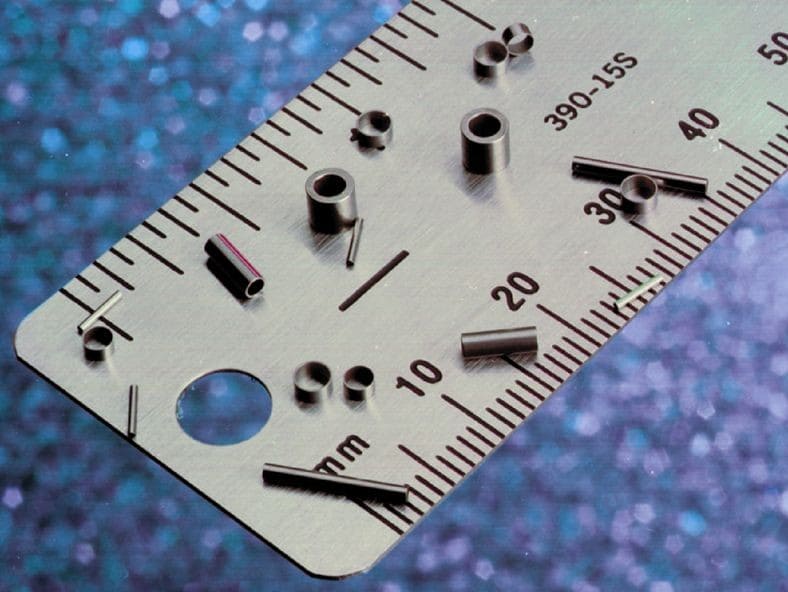

Products cut using hydro cutting have clean, smooth cuts without any burrs. Since no heat treatment is used during the cutting process, the material properties like temperature resistance and color are not altered. Depending on the strength of the material being cut and the desired rate of production, hydro cutter jets spray water at pressures between 30,000 and 90,000 PSI.

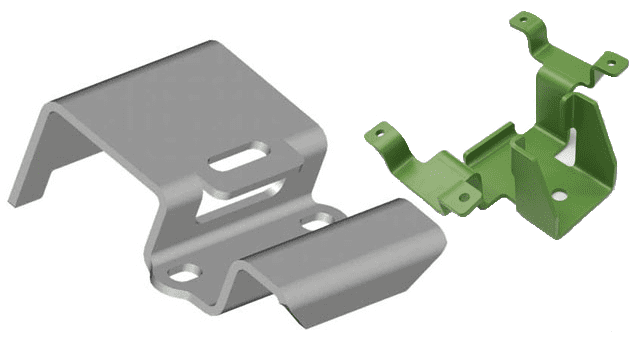

The automotive, aerospace, manufacturing, food processing, lumber, architectural, construction and electronic industries all use products that go through the hydro cutting process during fabrication. Machinery components like gears, tiles, mirrors, car, train and plane components and stone flooring can all be shaped by the water jet cutting process.

Most modern water jet cutting machines are fully automated and use CNC (computer numerical controlled) software to determine and control the route of the water stream. Therefore, labor costs are low since the only manual work involved in water jet cutting relates to setup, repairs and computer operation. A drawing of the desired shape or design is downloaded into CAD/CAM software, and the water nozzles follow its path.

Close precision reduces waste and the need for secondary machining processes. Hydro cutting doesn't create any harmful dust or particles that workers could inhale, and produces high volumes of products with minimal scrap material. Also, unlike many other cutting processes, hydro cutting does not involve the use or generation of heat, which reduces risks to workplace safety.

The hydro cutters are mostly made of stainless steel and contain a water reservoir, abrasive containers and a high pressure water pump with a nozzle attached. Both the water and any abrasives used are recycled many times through the machine. They are combined in a mixing tube, shot through a nozzle at high pressure and then re-circulated back into their separate storage areas.

Broaching

Broaching CNC Machining

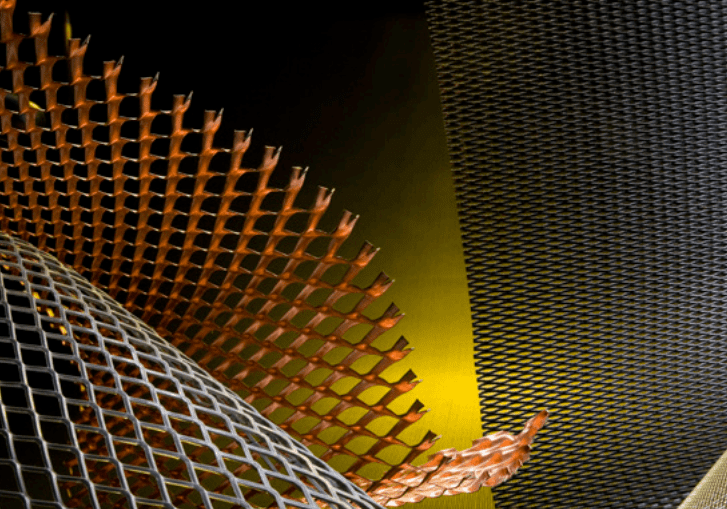

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

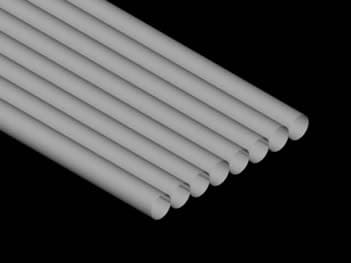

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services