Seastrom Manufacturing Co., Inc.

Seastrom Manufacturing Co., Inc.Request A Quote

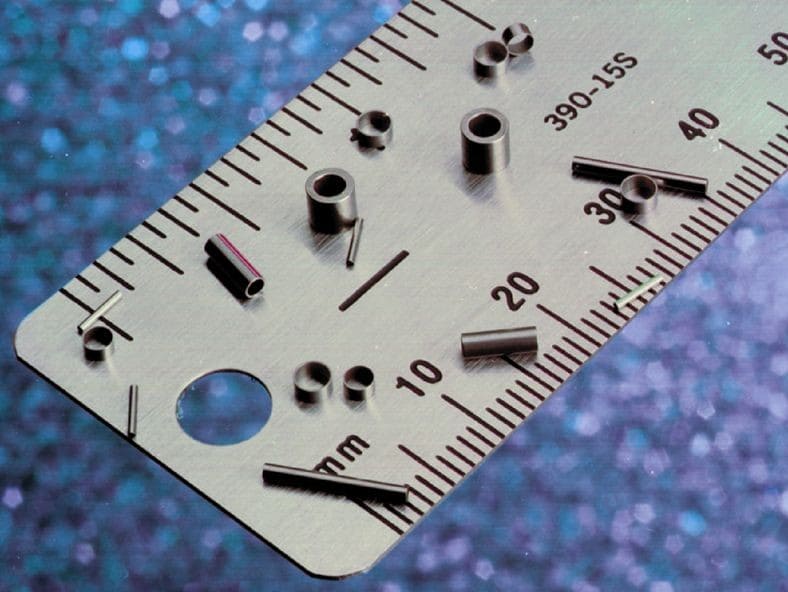

TWIN FALLS, IDIn 1928, Wensil Seastrom founded a company in a neighbor’s garage in Glendale, California. He most likely never imagined the company would become known as one of the nation’s leading manufacturers of standard and custom assembly hardware. Today, Seastrom Manufacturing is a family run corporation, located in a state-of-the-art 100,000 square foot facility in Twin Falls, Idaho. Making this move in 1994, would allow for continued growth and the ability to technically advance their manufacturing process, improving production speeds and reducing lead times. Seastrom Manufacturing understands the importance of producing quality custom and standard parts, and because of this, has earned the distinction as an approved supplier for most major aerospace, automotive, and commercial manufacturers. Customers receive immediate price and availability with a comprehensive online catalogue of standard washers and fasteners. Seastrom Manufacturing offers over 44,000 part numbers ready for same day shipping delivered right to your door. You’ll find flat round washers, spring clips, spacers, shoulder washers, lock washers, clamps, brackets, expansion plugs and much more. Seastrom also manufactures pins, terminals, and connectors. Aside from the vast inventory of stocked parts, Seastrom Manufacturing can also modify any of our standard part numbers to meet a customer’s distinct application, thus reducing the cost of tooling. Our custom capabilities include standard and miniature metal stamping, CNC machining, four-slide, screw machining, and water jet technology. These capabilities are complemented by a full engineering and tooling department. Seastrom has short and long run capabilities in most metallic and non-metallic materials from our large material warehouse. Secondary operations, assembly and special packaging are also offered to our customers. Seastrom Manufacturing is DFARS, REACH, RoHS, Nadcap and ITAR compliant and is ISO9001/AS 9100 certified.

Broaching

Broaching CNC Machining

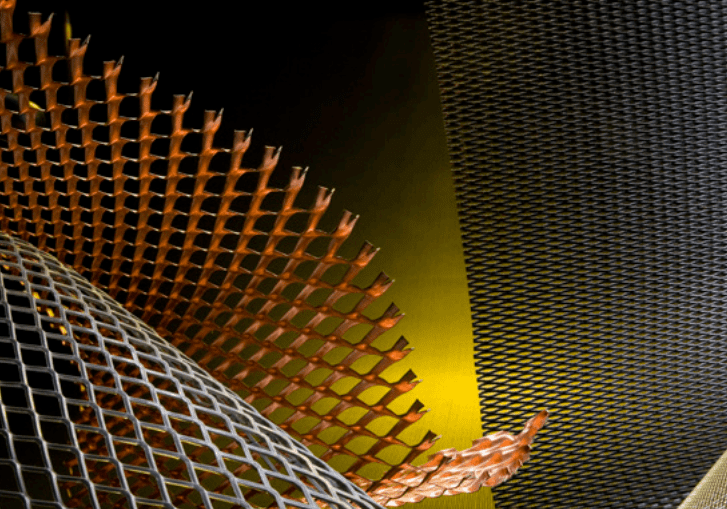

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

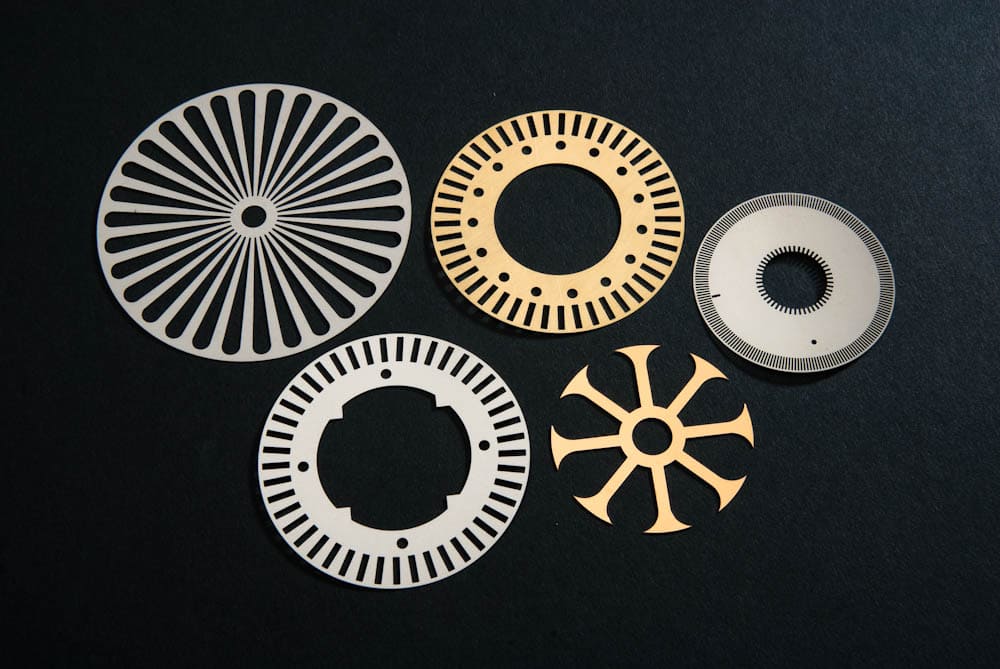

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

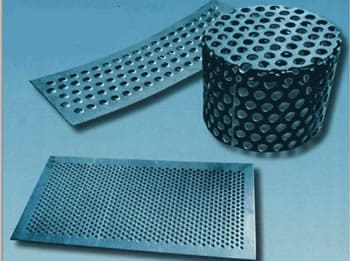

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

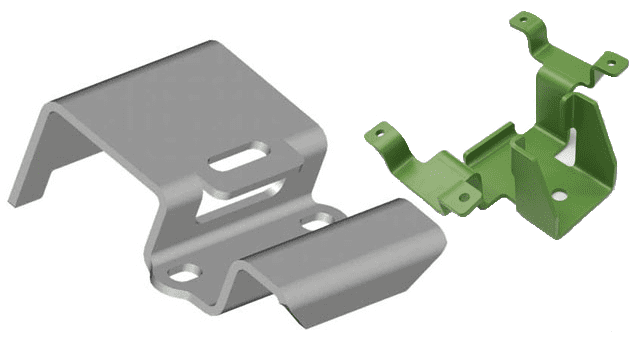

Metal Stampings Sheet Metal Fabrication

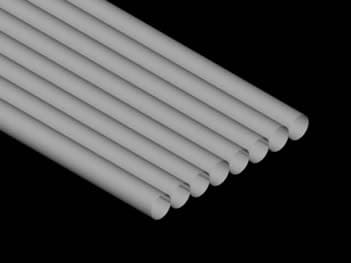

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services